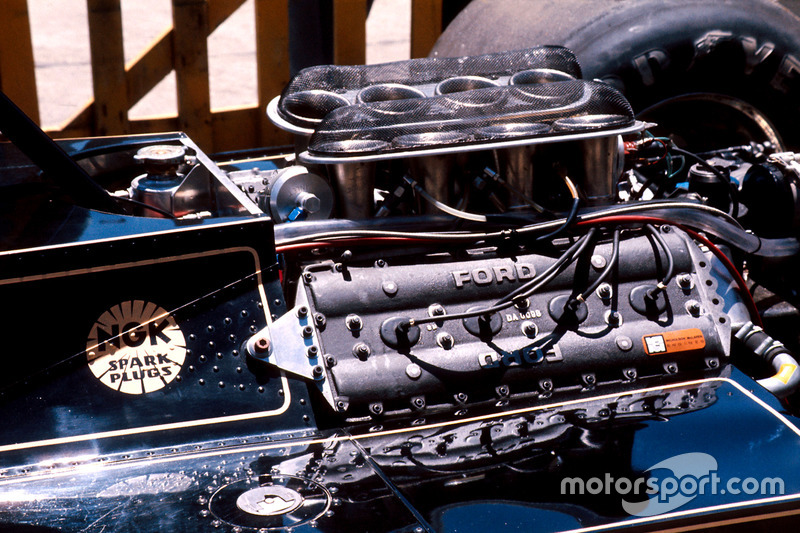

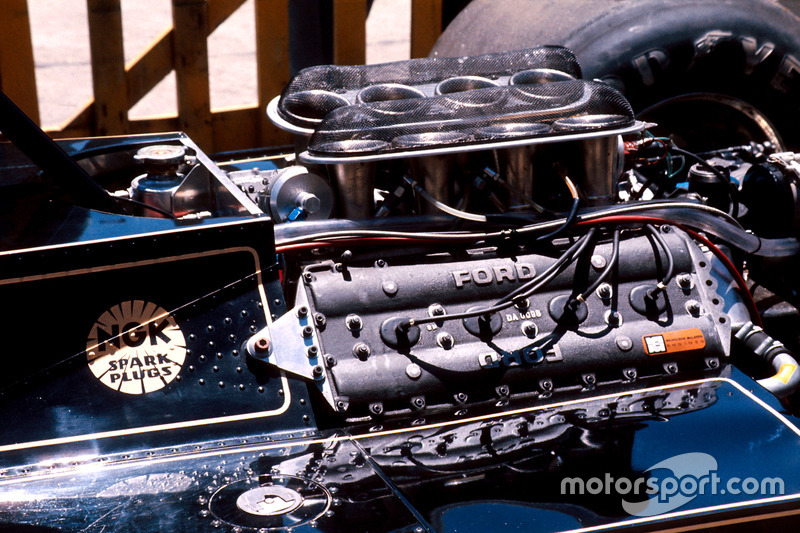

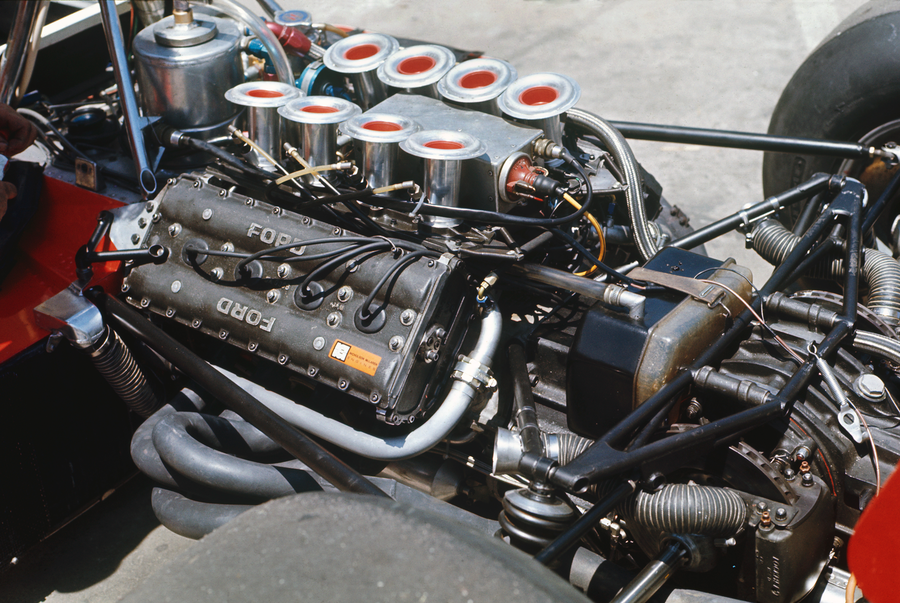

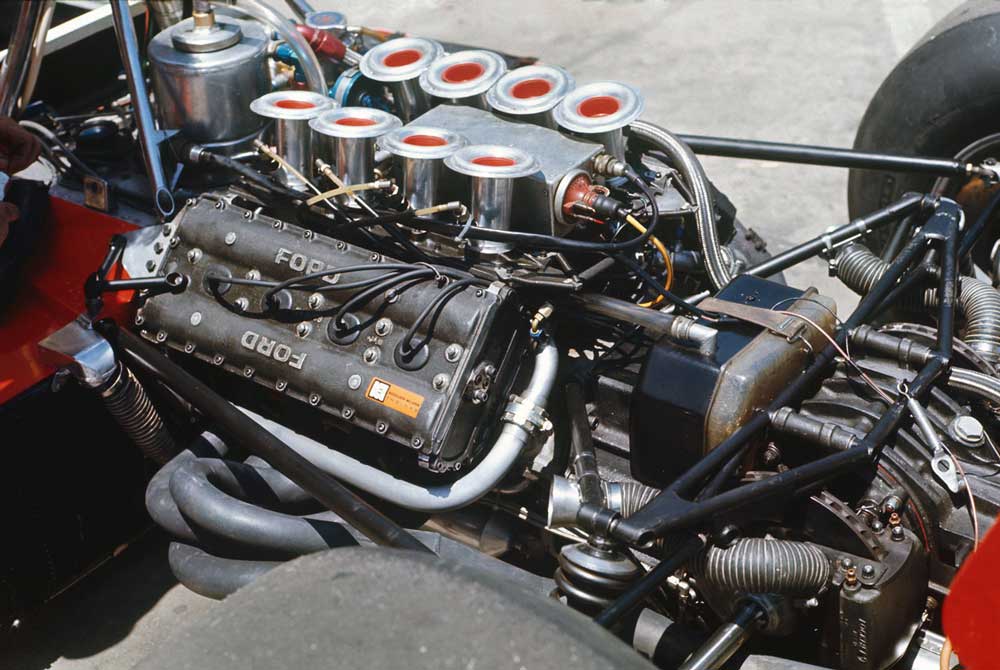

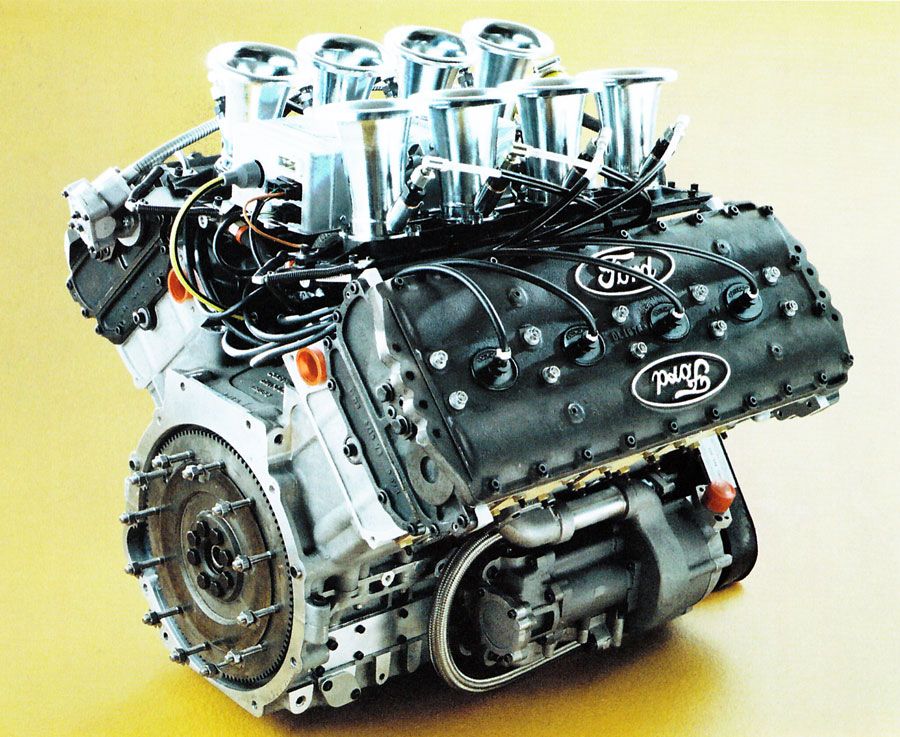

The Ford Cosworth DFV

The Ford Cosworth DFV by Andrew NoakesGet other Ford repair manuals here The Ford Cosworth DFV engine first appeared at the Dutch Grand Prix in 1967, powering the Lotus 49s of Graham Hill and Jim Clark. Hill claimed pole position, and Clark won the race - a remarkable debut for an engine that went on to become the most successful ever in Formula One. The DFV won a remarkable 155 Grands Prix, the last of which was in 1983, 16 years after its debut. Published to coincide with the DFV's 40th anniversary, this beautifully produced book tells the full story of this remarkable engine's development and evolution. The Ford Cosworth DFV by Andrew Noakes

|

Our company have been shipping workshop manuals to Australia for the past 7 years. This site is devoted to the selling of workshop and repair manuals to just Australia. We continue to keep our workshop and repair manuals always in stock, so right as you order them we can get them freighted to you conveniently. Our delivering to your Australian regular address by and large takes 1 to two days.

Workshop and repair manuals are a series of effective manuals that normally focuses on the routine maintenance and repair of motor vehicles, covering a wide range of makes. Workshop manuals are targeted primarily at DIY owners, rather than expert garage mechanics.The manuals cover areas such as: CV boots,starter motor,spring,camshaft sensor,fuel filters,blown fuses,trailing arm,exhaust manifold,crank case,batteries,gearbox oil,wiring harness,suspension repairs,alternator belt,oil seal,clutch pressure plate,petrol engine,rocker cover,clutch cable,turbocharger,camshaft timing,radiator hoses,engine control unit,steering arm,glow plugs,pcv valve,spark plug leads,clutch plate,wheel bearing replacement,overhead cam timing,crank pulley,radiator flush,tie rod,gasket,fuel gauge sensor,CV joints,stub axle,Carburetor,replace tyres,brake servo,window replacement,anti freeze,signal relays,brake pads,o-ring,seat belts,ABS sensors,stripped screws,valve grind,exhaust gasket,bleed brakes,window winder,shock absorbers,ball joint,oxygen sensor,adjust tappets,master cylinder,cylinder head,caliper,brake rotors,alternator replacement,warning light,distributor,slave cylinder,change fluids,brake piston,bell housing,exhaust pipes,sump plug,knock sensor,replace bulbs,engine block,oil pump,injector pump, oil pan,diesel engine,conrod,fix tyres,drive belts,brake shoe,coolant temperature sensor,spark plugs,stabiliser link,ignition system,head gasket,grease joints,brake drum,throttle position sensor,headlight bulbs,radiator fan,water pump,piston ring,supercharger,thermostats,pitman arm,crankshaft position sensor

>

>

0 Items (Empty)

0 Items (Empty)