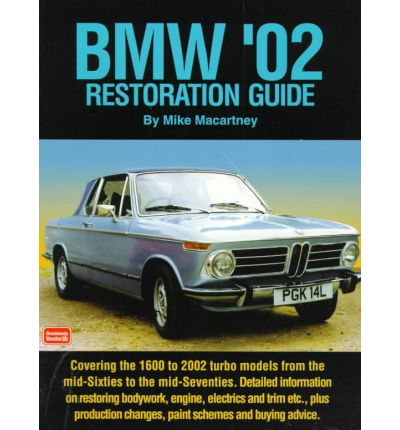

BMW '02 Restoration Guide

BMW '02 Restoration Guide by Mike Macartney

Get other BMW repair manuals here

Restore it right the first time! This information-packed guide provides all the information you need to restore your prized BMW. Contents cover 1600 to 2002 turbo models from the mid-60's to the mid-70's, and include detailed information on restoring bodywork, chassis, engine and trim. Includes production changes, color schemes and history. Integracar tries to render a wide scope of owners guides. Then again maintenance manuals can be produced for numerous different nations and the automobiles manufactured for those countries. Due to this fact not all owners manuals may be best suited for your individual vehicle. If you have enquiries whether a specific owners manual is ideal for your automobile kindly get in contact with us here

0 Items (Empty)

0 Items (Empty)