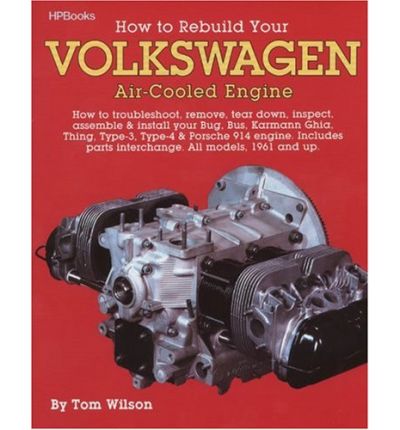

Rebuild Aircooled VW Engines HP255

Rebuild Aircooled VW Engines HP255 by Tom Wilson

Get other VW repair manuals here

A guide to engine rebuilding includes discussions of removal, parts indentification, cylinder head reconditioning, and engine assembly Integracar tries to make available a diverse array of workshop guides. But owners manuals can be created for assorted countries and the motor cars engineered for those nations. That means not all service manuals may be acceptable for your particular car. If you have queries whether a particular repair manual is relevant for your automobile kindly contact us here

0 Items (Empty)

0 Items (Empty)