Triumph Motorcycle Restoration

Triumph Motorcycle Restoration by Timothy RemusGet other Triumph Motorbike repair manuals here Triumph Twins first burst onto the scene in 1938, and continued to improve up to their demise in the 1980's. This book covers the restoration of these classic and beloved machines, and is the only one to do so. In full-colour format, it includes two start-to-finish assemblies, with sidebars to explain how to correctly lace a wheel, which metal coatings are correct for which year, and other valuable information. Written by Triumph restoration expert Gary Chitwood and well-known how-to author Timothy Remus, all the projects are practical, clearly explained, and fully illustrated - including the disassembly and restoration of both a Bonneville 1963 and a Bonneville 1969, in complete step-by-step stages with full illustrations, plus the overhaul and assembly of an engine for the 1969 model. It may be good to have a book that explains how to install a wheel in a frame, but how much better is it when this is shown as well in full colour - the wheel being slipped up between the fork legs and the axle sliding through the fork and into the hub. With over 400 colour photos, this book offers 144 pages of hard-core how-to help for anyone who wants to repair or restore their own Triumph twin. Integracar aims to present a substantial array of owners manuals. Although owners manuals can be designed for foreign countries and the motorbikes developed for those nations. Hence not all workshop manuals may be acceptable for your selected motorcycle. If you have queries whether a particular owners manual is proper for your motorcycle do not hesitate to get in touch with us here Triumph Motorcycle Restoration by Timothy Remus

|

Our company have been dealing workshop,maintenance,service manuals to Australia for 7 years. This web site is fully committed to the sale of workshop and repair manuals to only Australia. We routinely keep our manuals in stock, so as soon as you order them we can get them supplied to you speedily. Our transport to your Australian standard address ordinarily takes 1 to two days.

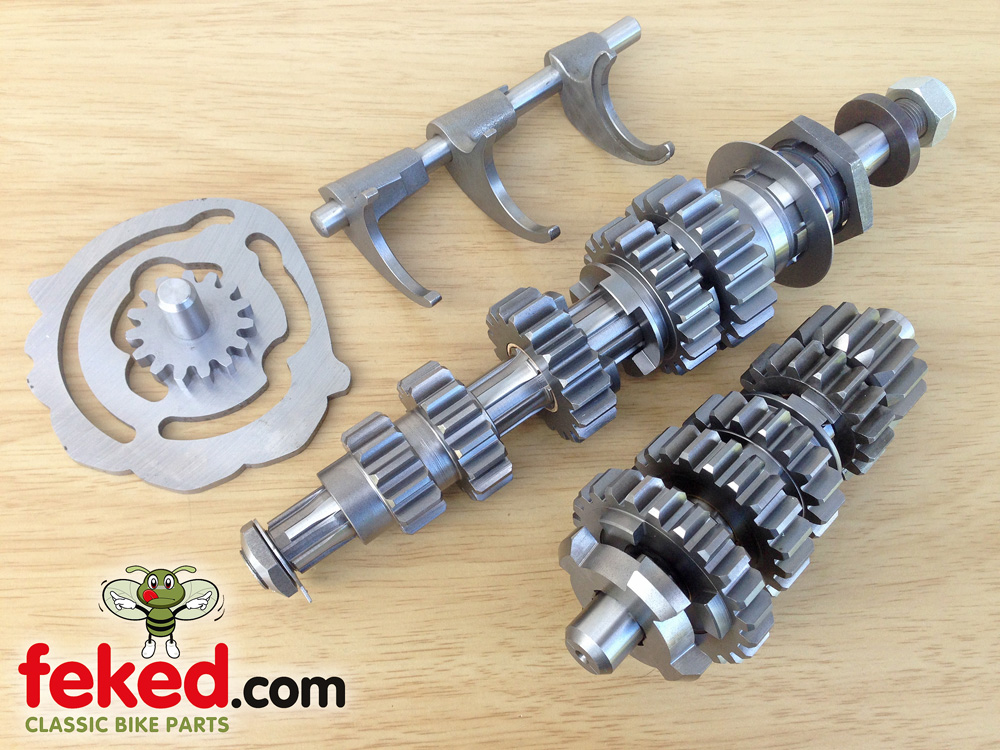

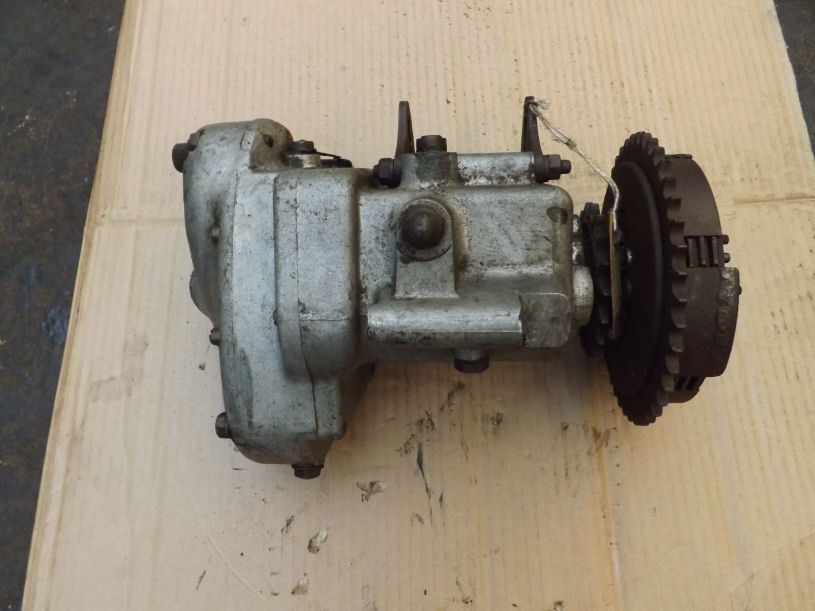

Workshop,maintenance,service manuals are a series of worthwhile manuals that chiefly focuses upon the maintenance and repair of automotive vehicles, covering a wide range of models. Workshop manuals are targeted chiefly at Do-it-yourself enthusiasts, rather than professional workshop mechanics.The manuals cover areas such as: Carburetor,crankshaft position sensor,tie rod,alternator replacement,conrod,shock absorbers,coolant temperature sensor,sump plug,gearbox oil,valve grind,brake piston,petrol engine,brake drum,bleed brakes,clutch plate,headlight bulbs,injector pump,alternator belt,radiator flush,oil pump,grease joints,ABS sensors,spark plug leads,slave cylinder,seat belts,wheel bearing replacement,stub axle,clutch cable,crank pulley,radiator hoses,camshaft sensor,master cylinder,adjust tappets,bell housing,glow plugs,warning light,head gasket,brake rotors,stabiliser link,distributor,exhaust pipes,stripped screws,brake shoe,knock sensor,steering arm,drive belts,brake servo,blown fuses,engine control unit,wiring harness,clutch pressure plate,radiator fan,pcv valve,overhead cam timing,CV joints,diesel engine,cylinder head,ball joint,spring, oil pan,caliper,starter motor,window winder,water pump,pitman arm,window replacement,camshaft timing,o-ring,batteries,gasket,fix tyres,exhaust gasket,turbocharger,brake pads,exhaust manifold,rocker cover,CV boots,oil seal,suspension repairs,fuel gauge sensor,thermostats,change fluids,replace tyres,piston ring,engine block,supercharger,crank case,throttle position sensor,spark plugs,trailing arm,oxygen sensor,anti freeze,signal relays,fuel filters,ignition system,replace bulbs

>

>

0 Items (Empty)

0 Items (Empty)