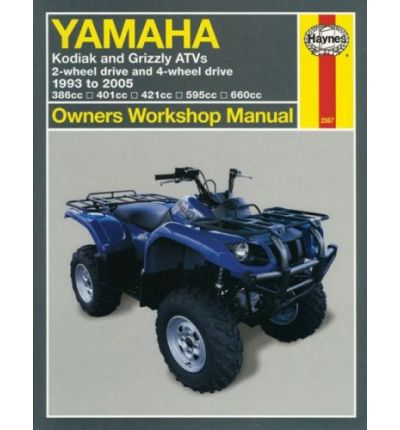

Yamaha Kodiak and Grizzly ATVs

Yamaha Kodiak and Grizzly ATVs by Alan Ahlstrand

Get other Yamaha Motorbike repair manuals here

Haynes offers the best coverage for cars, trucks, vans, SUVs and motorcycles on the market today. Each manual contains easy to follow step-by-step instructions linked to hundreds of photographs and illustrations. Included in every manual: troubleshooting section to help identify specific problems; tips that give valuable short cuts to make the job easier and eliminate the need for special tools; notes, cautions and warnings for the home mechanic; color spark plug diagnosis and an easy to use index. Integracar aims to furnish a sizeable selection of maintenance guides. Never the less workshop manuals can possibly be manufactured for assorted countries and the vehicles built for those countries. Which means that not all repair manuals may be ideal for your specific motorbike. If you have questions whether a selected repair manual is accurate for your motorbike do not hesitate to contact us here

0 Items (Empty)

0 Items (Empty)