The Life of Senna

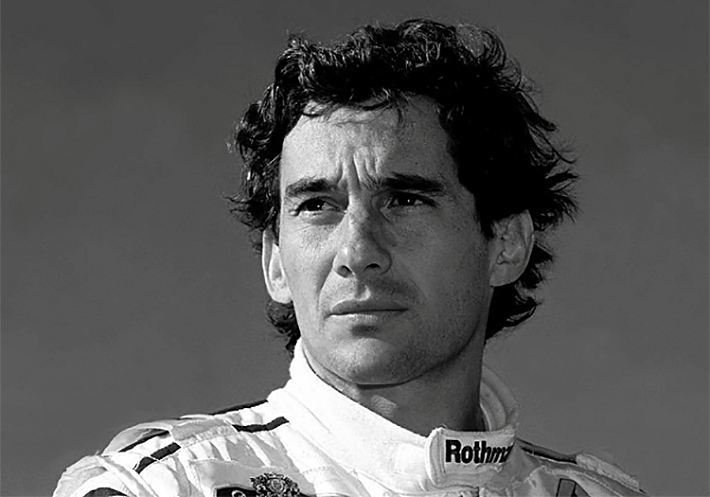

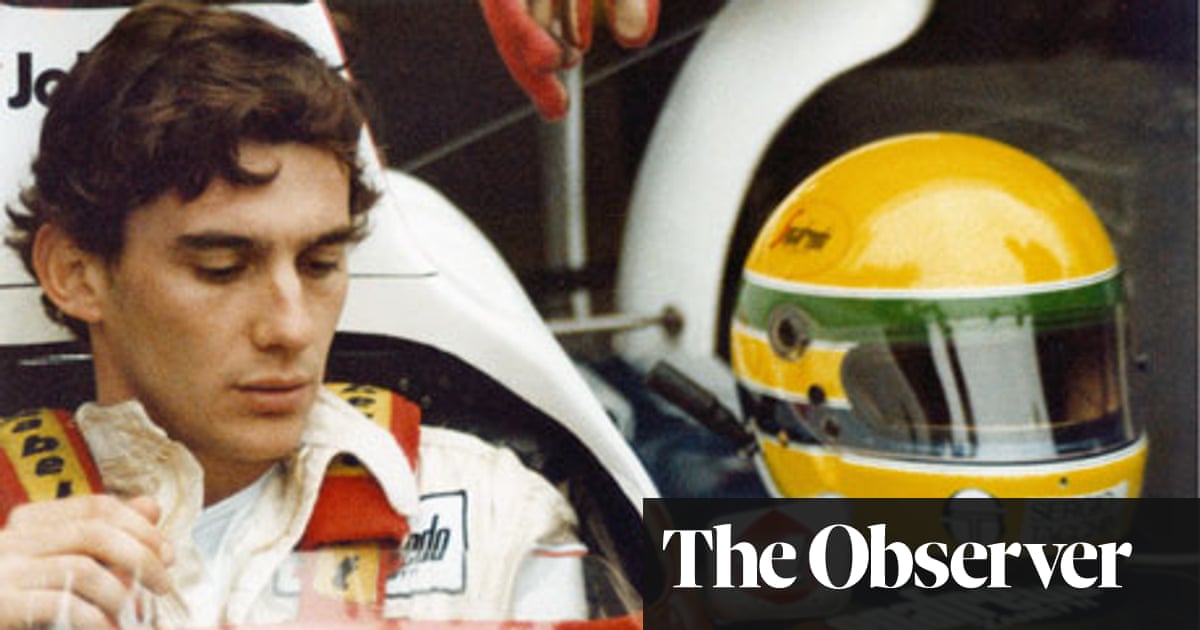

The Life of Senna by Tom RubythonAyrton Senna was, in many peoples' opinions, the greatest Formula One driver to have ever raced. Over 2 million people watched his shocking crash on television, during the San Marino Grand Prix, on Sunday 1st May, 1994. The knowing knew he was dead when his car finally came to rest on that fateful day. Although a host of biographies have been published, none have fully researched his life and character and exposed his extraordinary driving brain. In this first full, and stunningly illustrated, account of his life, the authors and their collaborators examine every detail of the driving maestro's life. From his earliest days, to his first race and on to his world championships, to his pole positions and finally to his death and its aftermath. 'He was the one driver so perfect that nobody thought anything could happen to him' Bernie Ecclestone 'Ayrton was the most committed of all. He had an air of invincibility around him. He put his entire body and mind into winning' Sir Frank Williams 'He established his own limits. When he reached those limits he wanted to beat them and establish new ones. I never knew how far he could go. I had an understanding but I didn't know'The only thing that existed was himself - and he had to be first' Gerhard Berger. The Life of Senna by Tom Rubython

|

Our company have been shipping workshop and repair manuals to Australia for the past seven years. This business is devoted to the trading of workshop manuals to only Australia. We continue to keep our workshop manuals available, so as soon as you order them we can get them shipped to you very quickly. Our freight shipping to your Australian street address normally takes 1 to 2 days.

Workshop and service manuals are a series of convenient manuals that chiefly focuses on the routine maintenance and repair of motor vehicles, covering a wide range of makes and models. Manuals are geared mainly at fix it yourself owners, rather than expert garage auto mechanics.The manuals cover areas such as: gearbox oil,clutch cable,change fluids,wiring harness,radiator fan,overhead cam timing,bleed brakes,suspension repairs,tie rod,window winder,ABS sensors,engine block,camshaft timing,crank pulley,fuel gauge sensor,warning light,brake servo,seat belts,stripped screws,head gasket,throttle position sensor,oxygen sensor,distributor,brake shoe,crank case,signal relays,radiator flush,o-ring,spark plugs,drive belts,grease joints,Carburetor,petrol engine,batteries,alternator replacement,replace tyres,crankshaft position sensor,piston ring,conrod,brake piston,pitman arm,fix tyres,cylinder head,exhaust manifold,spring,rocker cover,supercharger,anti freeze,window replacement,ignition system,steering arm,headlight bulbs,clutch plate,brake pads,wheel bearing replacement,alternator belt,knock sensor,master cylinder,gasket,water pump,thermostats,starter motor,valve grind,spark plug leads,ball joint,sump plug,replace bulbs,slave cylinder,CV joints,exhaust gasket,stabiliser link,camshaft sensor,glow plugs,injector pump,clutch pressure plate,brake drum,fuel filters,brake rotors,trailing arm,oil pump,coolant temperature sensor,diesel engine,shock absorbers,exhaust pipes,bell housing, oil pan,radiator hoses,engine control unit,caliper,turbocharger,CV boots,adjust tappets,oil seal,blown fuses,pcv valve,stub axle

-and-iot_vaaka-front.jpg width=676 height=423/>>

-and-iot_vaaka-front.jpg width=676 height=423/>>

0 Items (Empty)

0 Items (Empty)