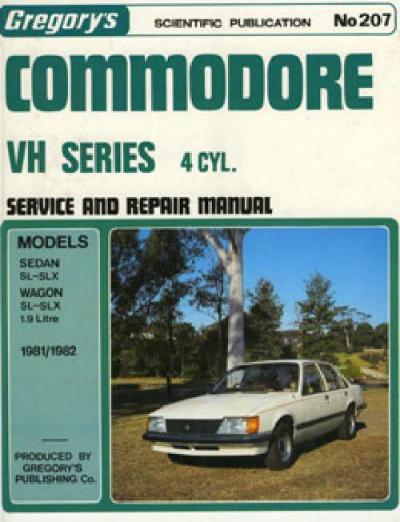

Holden Commodore VH 4 cyl 1981 1982 Gregorys Service Repair Manual

Holden (Vauxhall/Opel) Astra 1991 - 1998 Haynes Owners Service & Repair Manual

Other Holden Astra Car Repair Manuals click here

NEW paperback

Holden (Vauxhall / Opel) Astra 1991 - 1998 Haynes Owners Service & Repair Manual UK manual covering the Opel/Vauxhall Astra 1991 - 1998, sold in Australia from August 1996 as the Holden "TR" series Astra. The engines covered are:

- Saloon, Hatchback, Estate and Van, Including Special/Limited Editions 1991 - 1998.

Engines Covered:

- 1.4 L (1389cc) SOHC 4 cylinder petrol (Engine codes 14NV, 14SE, C14NZ, X14NZ & C14SE)

- 1.4 L (1389cc) DOHC 4 cylinder petrol (Engine code X14XE "Ecotec")

- 1.6 L (1598cc) SOHC 4 cylinder petrol (Engine codes C16NZ, C16SE, X16SZ & X16SZR)

- 1.6 L (1598cc) DOHC 4 cylinder petrol (Engine code X16XEL "Ecotec")

- 1.8 L (1796cc) SOHC 4 cylinder petrol (Engine code C18NZ)

- 1.8 L (1796cc) DOHC 4 cylinder petrol (Engine codes C18XE, C18XEL "Ecotec" & X18XE "Ecotec") - there is more detail about this item at the full website (you are viewing a mobile version)

| Stock Info: | Out of Print |

0 Items (Empty)

0 Items (Empty)