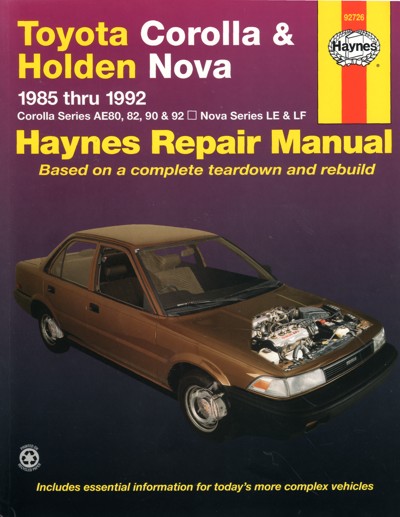

Toyota Corolla Holden Nova 1985-1992 Haynes Service Repair Manual

|

Does NOT include all-wheel drive information. Inside this manual you will find: Routine Maintenance, tune-up procedures, engine repair, cooling and heating, air-conditioning, fuel and exhaust, emissions control, ignition, brakes, suspension and steering, electrical systems and wiring diagrams. Haynes repair manuals can save you money on maintenance and repair bills. Step-by-step procedures and illustrations guide you through every job, from basic maintenance and troubleshooting, to complete teardown rebuild.

|

The name Corolla is piece of Toyota s naming custom of utilizing names extracted within the Toyota Crown for sedans. The Corolla has usually been exclusive inside Japan with Toyota Corolla Store places, plus produced inside Japan with a twin, called the Toyota Sprinter till 2000.

Early models were largely rear-wheel drive, whilst later models have been front-wheel drive. The Corolla s conventional competitors have been the Nissan Sunny, introduced the same year because the Corolla inside Japan as well as the later Honda Civic. The Corolla s chassis designation code is "E", because described inside Toyota s chassis plus engine codes.

Rear-wheel drive usually places the engine inside the front of the car as well as the driven wheels are situated at the back, a configuration termed as front-engine, rear-wheel drive design. The front mid-engine, back mid-engine plus back engine layouts are additionally employed. This was the conventional car design for many cars up till the 1970s plus 1980s. Nearly all motorcycles plus bicycles employ rear-wheel drive also, either by driveshaft, chain, or belt, because the front wheel is turned for steering, plus it will be extremely difficult plus complicated with "bend" the drive device about the turn of the front wheel. A fairly uncommon exception is with all the moving bottom bracket kind of recumbent bike, where the whole drivetrain, including pedals plus chain, pivot with all the steering front wheel.

Overhead camshaft, commonly abbreviated with OHC, is a valvetrain configuration that places the camshaft of a internal combustion engine of the reciprocating kind in the cylinder heads plus forces the valves or lifters inside a more direct way compared with overhead valves plus pushrods.

A double overhead camshaft valvetrain design is characterised by 2 camshafts positioned in the cylinder head, 1 running the consumption valves plus 1 running the exhaust valves. This shape reduces valvetrain inertia over a SOHC engine, because the rocker arms are reduced inside size or eliminated. A DOHC shape allows a wider angle between consumption plus exhaust valves than SOHC machines. This may permit for a less limited airflow at high engine speeds. DOHC with a multivalve shape equally enables the maximum location of the spark connect, which, improves combustion efficiency. Engines that have multiple bank of cylinders with 2 camshafts inside total stay SOHC; except every cylinder bank has 2 camshafts --- these latter are DOHC, plus are frequently well-known as quad cam . The term twin cam is imprecise, nevertheless might usually refer with a DOHC engine. Many producers employ a SOHC inside a multivalve shape. Additionally, not all DOHC motors are multivalve machines. DOHC cylinder heads existed before multivalve cylinder heads appeared inside the 1980s. Today, still, DOHC is occasionally confused with multivalve heads, because most contemporary DOHC motors have between 3 plus five valves per cylinder --- yet multivalve plus DOHC are separate distinctions.

The Corolla E80 was the fifth generation of vehicles available by Toyota below the Corolla nameplate. It was furthermore available beneath the Sprinter nameplate.

The fifth generation is usually considered the top Corolla whenever calculated against its contemporaries, plus certain 3.3 million units were yielded. This model, from 1983, moved the Corolla into front-wheel drive, except for the AE85 plus AE86 Corolla Levin / Sprinter Trueno models that continued found on the elder rear-wheel drive platform, together with the three-door "liftback", three-door van plus five-door wagon of the past generation, that have been nevertheless being yielded.

The front-wheel-drive wheelbase was today 95.6 inside.

It was the initial Corolla with top the New Zealand top-ten lists, ending Ford s dominance of which marketplace. A smaller hatchback range, called the Corolla FX inside Japan as well as the Corolla Compact inside Germany, arrived inside October 1984 found on the front-wheel-drive platform. The three- plus five-door hatchbacks resembled the Corolla sedan with a truncated back deck plus torso. Although there was clearly a five-door liftback model of the standard Corolla, the less FX hatchback was available alongside it. The Corolla FX changed the Toyota Starlet inside North America.

A DOHC 16-valve engine, designated 4A-GE, was added inside 1983 found on the rear-drive vehicles. It became a 1.6 L I4 plus yielded an impressive 124 PS, turning the Levin/Trueno, Corolla GT coup plus Corolla GT-S into a what was arguably a sports auto. The three-door FWD hatchback was additionally accessible with this engine; it was termed as the Corolla FX-16 inside North America. This engine was additionally combined with all the front-drive transaxle with energy the mid-engined Toyota MR-2.

The Sprinter sports vehicles, inside two-door coup plus three-door liftback types, were notable to be the line s initially employ of pop-up headlamps, that the similar Corolla Levin sports models didn't have.

Australian marketplace engines:

2A-C 1.3 L I4, 8-valve SOHC, carb,

4A-C 1.6 L I4, 8-valve SOHC, carb, 78 hp

4A-GE 1.6 L I4, 16-valve DOHC, EFI, 115 hp

Australian marketplace chassis:

AE80 --- FWD 4-door sedan /5-door hatchback

AE82 --- FWD 4-door sedan /5-door hatchback /5-door Seca Liftback

AE86 --- RWD 3-door hatchback

The carburetor functions about Bernoulli s principle: the quicker air moves, the lower its static stress, as well as the high its dynamic stress. The throttle linkage refuses to straight control the flow of fluid gas. Instead, it actuates carburetor mechanisms that meter the flow of air being pulled into the engine. The speed of the flow, plus consequently its stress, determines the amount of gas drawn into the airstream.

Whenever carburetors are utilized inside aircraft with piston motors, specialized designs plus attributes are required with avoid gas starvation throughout inverted flight. Later machines selected an early shape of gas injection well-known as a stress carburetor.

Many creation carbureted, because opposed with fuel-injected, machines have a single carburetor along with a matching consumption manifold which divides plus transports the air gas mixture with the consumption valves, though certain motors utilize several carburetors about split heads. Multiple carburetor machines were furthermore popular enhancements for changing machines inside the USA within the 1950s with mid-1960s, in addition to throughout the following decade of high-performance muscle vehicles fueling different chambers of the engine s intake manifold.

Older machines employed updraft carburetors, where the air enters from under the carburetor plus exits from the best. This had the benefit of not flooding the engine, because any fluid gas droplets might fall from the carburetor rather of into the consumption manifold; it additionally lent itself with utilize of a oil bathtub air cleaner, where a pool of oil under a mesh element under the carburetor is sucked up into the mesh as well as the air is drawn by the oil-covered mesh; this was an efficient program inside a time whenever paper air filters didn't exist.

Beginning inside the late 1930s, downdraft carburetors were the top sort for automotive utilize inside the United States. In Europe, the sidedraft carburetors changed downdraft because free room inside the engine bay reduced as well as the utilize of the SU-type carburetor improved. Many little propeller-driven aircraft machines nevertheless utilize the updraft carburetor shape.

Outboard engine carburetors are usually sidedraft, considering they should be stacked 1 over the different inside purchase with feed the cylinders inside a vertically oriented cylinder block.

1979 Evinrude Type I marine sidedraft carburetor

The principal drawback of basing a carburetor s surgery about Bernoulli s Principle is the fact that, being a fluid dynamic device, the stress reduction inside a Venturi seems with be proportional with the square of the consumption air speed. The gas jets are much small plus limited primarily by viscosity, thus which the gas flow seems with be proportional with the stress difference. So jets sized for full energy tend with starve the engine at lower speed plus element throttle. Most commonly this has been corrected by utilizing numerous jets. In SU plus additional movable jet carburetors, it was corrected by differing the jet size. For cold beginning, a different principle was employed inside multi-jet carburetors. A flow resisting valve called a choke, synonymous with the throttle valve, was located upstream of the key jet with minimize the consumption stress plus suck extra gas from the jets.

The 1.3 L 2A was yielded from 1979 by 1989. 2A motors inside 1982 onwards AL20 Tercels have a somewhat different valve cover plus timing belt cover than early AL11 Tercels, and an automatic choke, plus automatically controlled hot air consumption program. It also offers high compression ratio, plus reformulated combustion chambers with enhance the gas economy plus emissions. All variants employed belt-driven SOHC eight-valve counter-flow cylinder heads with a single downdraft carburetor.

2A, 2A-L, 2A-LC

Output:

65 PS at 6,000 rpm plus 98 Nm at 3,800 rpm

Applications:

AE80 Corolla 1983--1985

AL11 Tercel 1979--1982

AL20 Tercel 1982--1984

2A-U, 2A-LU

With Toyota TTC-C catalytic converter.

Output:

75 PS at 6,000 rpm plus 106 Nm at 3,600 rpm

The valve train is the mechanical program responsible for procedure of the valves. Valves are of the poppet kind, though various others have been developed including sleeve, slide, plus rotary valves.

Its cause is with seal the cylinders with confirm maximum compression plus avoid leakage of coolant or engine oil into the cylinders; as a result, it happens to be the many important sealing application in almost any engine, plus, because piece of the combustion room, it shares the same strength specifications because alternative combustion room components.

MLS or Multiple Layers Steel -- Many contemporary head machines are yielded with MLS gaskets. These usually comprise of 3 levels of steel. The contact encounters are coated with a rubber-like coating including Viton which adheres with the cylinder block plus cylinder head whilst the wider center layer is left bare.

Solid copper -- a strong sheet of copper, plus usually demands specialized machining called o-ringing which places a part of cable about the circumference of the cylinder with bite into the copper. Whenever this might be done copper gaskets are very durable. Recently businesses have began producing copper gaskets with key sealing wiring permitting their retrofit into motors without the treatment of the engine block for machine function.

Composite -- an elder technologies. Typically these are made of asbestos or graphite yet are more inclined with blowouts than new gaskets. Asbestos gaskets are becoming increasingly uncommon due with wellness concerns.

Elastomeric -- a gasket kind selected by Rover about their K Series motors. It used the steel core plate with molded inside spot silicone rubber beads with seal oil plus coolant passages. The bores were sealed by rolled steel fire rings inside a more traditional way. The idea behind the gasket shape was with provide a creation variation of the development utilized inside F1 machines at the time. The authentic application of the gasket found on the small versions of the K Series was truly lucrative. But, an engine redesign lead to persistent difficulties with all the shape -- the joint interface became unstable as well as the gasket couldn't deal.

The expense of the substitution gasket is normally not extreme, however, the cost of total repair is greatly excellent. This really is considering removing/replacing an engine head is truly time intensive - about 75% of expense is work. Furthermore, untreated blown gaskets normally really damage the engine, then requiring a lot more pricey function.

The routine internal combustion engine is a water-cooled four-stroke petrol shape. It utilizes 3 circuits of functioning fluids:

Combustible air/fuel mixture

Water based coolant, normally with glycol mixed

Motor oil for lubrication

These are all important, however should not be enabled with intermix. Apart from sealing the cylinder, the head gasket moreover seals water plus oil conduits involving the head plus block. Any connectivity between them might result engine failure, or noticeable issues like burning oil. Blue exhaust smoke can be indicative of oil burning. White exhaust smoke is an signal of coolant burning, another signal of head gasket wear.

Occasionally, the compression inside the cylinder may result a leak with shape inside the gasket as well as the gasket must be changed, or serious damage may take spot. This problem has been exacerbated by the utilization of aluminum instead of iron cylinder heads; when lighter than iron, aluminum has a much better thermal expansion rate, which causes a good deal more strain with be located found on the head gasket. Engine makers have responded to the by adding a non-stick coating like Teflon with the surface of the head gasket.

If the gasket fails, a range of difficulties could happen, from compression reduction, with exhaust gases being forced into the cooling program, leading with the engine overheating plus improved engine wear due with the engine oil being mixed with antifreeze. Coolant will leak into the cylinders, causing the exhaust with matter steam as well as the catalytic converter with be damaged. If a extremely big amount of coolant does this, hydrolock may happen, causing extensive engine damage. Occasionally, all which might result whenever a head gasket is blown is excessive steam erupting within the tailpipe; yet the engine can act plus drive like regular, till all coolant is gone as well as the engine overheats. In other occurrences, compression leaks into little spaces involving the gasket plus either the cylinder head or engine block trap air which is then introduced whenever the engine is turned off, that then escape into the coolant plus create air pouches. Occasionally, these air purse will receive caught inside the machines coolant thermostat, causing it with remain closed plus further the overheating matter, therefore creating nonetheless more voids amongst the gasket as well as the engine. Air purse will equally result the engine with expel coolant into the overflow or expansion tank, therefore reducing the amount of coolant the engine has accessible with remain cool.

A damaged head gasket will let gases with leak between cylinders.

The condition of the head gasket is usually investigated by checking the compression stress with a stress gauge, or greater, a leak-down test, and/or noting any indication of combustion gases inside the cooling program about a water-cooled engine. Oil mixed with coolant plus excessive coolant reduction without obvious cause, or presence of carbon monoxide or hydrocarbon gases inside the expansion tank of the cooling program will equally be signs of head gasket difficulties. A superior signal of head gasket failure about water-cooled machines is the presence of the substance which resembles mayonnaise inside the oil, frequently with be watched found on the dipstick, or oil filler limit. But, the presence of the substance is not conclusive proof of head gasket failure, because oil might blend with all the coolant through alternative routes.

A leaking head gasket is categorized because either exterior or internal. An outside leak is diagnosed because oil plus coolant accumulating under the engine. The presence of coolant is recognized by shining a black light about what appears with be an oil leak; the appearance of coolant can show up beneath the black light. External leaks will equally appear because earlier described inside the oil. An internal leak may commonly be diagnosed by excessive coolant accumulating inside the expansion tank together with the presence of hydrocarbons inside the shape of foam. The possibility of vapors or condensation &/or water build up from an exterior breather or catch tank within the head could equally result a somewhat buildup of froth or gunk inside the oil yet is very unlikely.

In December 1988, Toyota created a joint venture with Holden called UAAI with build plus marketplace the Toyota Corolla because the Holden Nova. This agreement paralleled 2 Corolla decades including both the E90 plus E100 series.

Australian marketplace engines:

4A-F --- 1.6 L I4, 16-valve DOHC, carb, 95 hp CS, CS Limited, CSX & Spirit

4A-FE --- 1.6 L I4, 16-valve DOHC, FI, narrow valve angle, 102 hp XL, SR5, CSi, CSi Limited, Olympic Spirit

4A-GE --- 1.6 L I4, 16-valve DOHC, FI, broad valve angle, 135 hp SX, FX-GT & GTi

6A-FC --- 1.4 L I4, 16-valve DOHC, carb, narrow valve angle, 81 hp SE

7A-FE --- 1.8 L I4, 16-valve DOHC, FI, narrow valve angle, 115 hp Seca RV & Seca Ultima

Australian marketplace chassis:

AE90 --- Sedan, Hatchback

AE92 --- Sedan, Hatchback, Seca

AE93 --- Hatchback, Seca

AE94 --- Sedan, Hatchback, Seca

AE95 --- Wagon

AE96 --- Seca

Note:

Corolla Liftback was called Seca inside Australia

The Corolla 4x4 wagon was introduced inside mid-1988, Hatchback, Seca & Sedan introduced mid-1989

SX is usually AE93 though about uncommon times they are found with be AE92R

The facelift series 2 models were introduced inside October 1992

6A-FC was just found inside SE hatchbacks plus early SE Sedans

Corollas with 7A-FE engine were AE94 Ultimas inside early 1992 plus AE96 Ultimas & RV s inside late 92 onwards

Engine tuning is the change, modification of the internal combustion engine or modification with its control device, otherwise termed as its ECU. It is conducted with give optimum performance, with strengthen an engine s force output, economy, or toughness. These objectives can be mutually exclusive, plus an engine can be detuned with regard with output inside exchange for greater economy or longer engine existence due with lessened strain about engine components.

It has a lengthy history, virtually because extended because the development of the car all together, originating with all the development of early racing vehicles, plus later, with all the post-war hot-rod movement. Tuning can describe a broad range of changes plus modifications, within the routine change of the carburetor plus ignition program with extensive engine overhauls. At the different end of the scale, performance tuning of a engine will include revisiting a few of the shape decisions taken at very an early stage inside the development of the engine.

Setting the idle speed, fuel/air mixture, carburetor balance, spark connect plus distributor point spaces, plus ignition timing were normal upkeep products for all elder machines as well as the final nevertheless imperative procedures inside setting up a racing engine. On contemporary machines, loaded with electronic ignition plus gas injection, certain or all these jobs are automated, though they nevertheless need regular calibration.

Performance tuning concentrates on tuning an engine for motorsport, though countless these cars not compete nevertheless very are built for show or leisure driving. In this context, the energy output, torque, plus responsiveness of the engine are of premium value, nevertheless security plus gas efficiency are moreover relevant. In races, the engine need to be sturdy enough with withstand the more strain located on it, so is usually far stronger than any mass-produced shape about that it can be based, and which the vehicle should carry enough gas. In certain, the transmission, driveshaft plus any additional load-transmitting powertrain components might have to be modified inside purchase with withstand the weight within the improved energy.

In all situations, individuals are interested inside improving the force output of a engine. Many perfectly tried plus tested techniques have been devised with achieve this, however, all really work with grow the rate of combustion inside a provided engine. This really is attained by placing more air/fuel mixture into the engine, improving compression ratio burning it more quickly, plus getting free of the waste items more quickly - this increases volumetric efficiency. In purchase with check the amount of the air/fuel mixture, air gas ratio meters are usually utilized. The fat of the gas might affect the performance of the car, thus gas economy is a competitive benefit. This also means which the performance tuning of a engine could happen inside the context of the development of the total car.

The particular methods with strengthen force include:

Increasing the engine displacement by 1 or both of 2 methods: "boring" - improving the diameter of the cylinders plus pistons, or by "stroking" - utilizing a crankshaft with a better throw.

Utilizing heavier or several carburetors, with create a more controllable air/fuel mixture with burn, plus with receive it into the engine more smoothly. In contemporary machines, gas injection is much more frequently utilized, plus can be modified inside a synonymous way.

Increasing the size and style of the poppet valves inside the engine, therefore decreasing the limitation inside the path of the fuel--air mixture entering, as well as the exhaust gases exiting the cylinder. Using numerous valves per cylinder results inside the same impact -- it is very usually harder to suit many little valves than with have bigger single valves due with the valve gear needed. However, it's difficult to locate room for 1 big valve inside the inlet along with a big valve found on the outlet side. Sometimes a big exhaust valve plus 2 small inlet valves are fitted for improved flow. As the stress produced throughout combustion offers more force with exhaust the waste gasses than the force accessible with inlet clean charged fuel, a greater inlet valve region is required with supply simpler flow. The 2 small inlet valves total region is heavier than which of the single exhaust valve and therefore offers which simpler inlet flow. This really is why exhaust valves are usually small inside location than the inlet valves.

Utilizing heavier bored, smoother, less contorted inlet manifold plus exhaust manifolds. This assists keep the velocity of gases. Similarly, the ports inside the cylinder head is enlarged plus smoothed with match. This really is termed cylinder head porting, commonly with all the help of a air flow bench for testing plus verifying the efficiency of the modifications. Manifolds with sharp turns force the air--fuel blend with separate at significant velocities because gas is a bit more thick than air.

The bigger bore can extend right by the complete exhaust program, utilizing greater diameter piping plus low back stress mufflers, plus by the consumption program, with bigger diameter airboxes plus high-flow, high-efficiency air filters. Muffler modifications can change the sound of the car s engine, commonly generating it louder; for several tuners this really is inside itself a desirable impact.

Increasing the valve starting height, by changing the profiles of the cams found on the camshaft, or the lift ratio of the valve rockers, or cam fans.

Optimizing the valve timing with boost burning efficiency - commonly this increases force at 1 range of working RPM at the cost of reducing it at others. For several applications this compromise is acceptable. This could commonly be accomplished by installing a differently profiled camshaft. See equally valve timing, varying valve timing.

Raising the compression ratio by reducing the size and style of the combustion room, that makes better utilize of the cylinder stress developed plus leading with more fast burning of gas, by utilizing heavier compression height pistons or slimmer head gaskets, or by utilizing a milling machine or "shaving" the cylinder head. High compression ratios could result engine knock except significant octane fuels are utilized.

Forced Induction; adding a turbocharger or perhaps a supercharger. The air/fuel blend entering the cylinders is improved by compressing the air. Further gains can be realized by cooling compressed intake air with an air-to-air or air-to-water intercooler.

With a gas with high power content plus by adding an oxidizer including nitrous oxide.

Reducing losses with friction by machining moving components with lower tolerances than will be acceptable for manufacturing, or by changing components. A popular illustration of the is, inside overhead valve machines, substituting the creation rocker arms with alternatives incorporating roller bearings inside the roller phoning the valve stem.

Reducing the "rotating mass", that comprises the crankshaft, connecting rods, pistons, plus flywheel. Doing thus will better throttle reaction due with lower rotational inertia, and also lower the car s total fat. This can be accomplished by utilizing alloy components rather of steel. But, the thick crankshaft will void the requirement for a flywheel.

Changing the tuning characteristics electronically, by changing the firmware of the EMS. This chip tuning usually functions considering contemporary machines are made with provide more force than needed, that is then reduced by the EMS with result in the engine work smoothly over a wider RPM range, with low emissions. This really is called de-tuning plus produces long-lasting motors as well as the ability with strengthen energy output later for facelift models. Recently emissions have played a big piece inside de-tuning, plus motors can usually be de-tuned with make the specific carbon output for taxes factors.

Lowering the underbonnet temperature, that has the impact of reducing the engine consumption temperature, consequently improving the force. This really is usually completed by installing a kind of thermal insulation about or about the exhaust manifold. This ensures which more heat is diverted out plus away within the underbonnet region.

Changing the place of the air intake, moving it away within the exhaust plus radiator systems with decrease intake temperatures. Additionally, the consumption is relocated with regions which have high air stress due with aerodyamic effects, causing effects synonymous with forced induction.

The choice of modification depends greatly found on the degree of performance enlargement desired, budget, as well as the characteristics of the engine with be modified. Intake, exhaust, plus chip updates are among the initially modifications prepared because they are the cheapest, create reasonably general improvements, while a different camshaft, for example, needs trading off smoothness at low engine speeds for improvements at excellent engine speeds.

Also, tuners can moreover employ analytical tools to aid evaluate plus predict the impact of modifications found on the performance of the car.

0 Items (Empty)

0 Items (Empty)