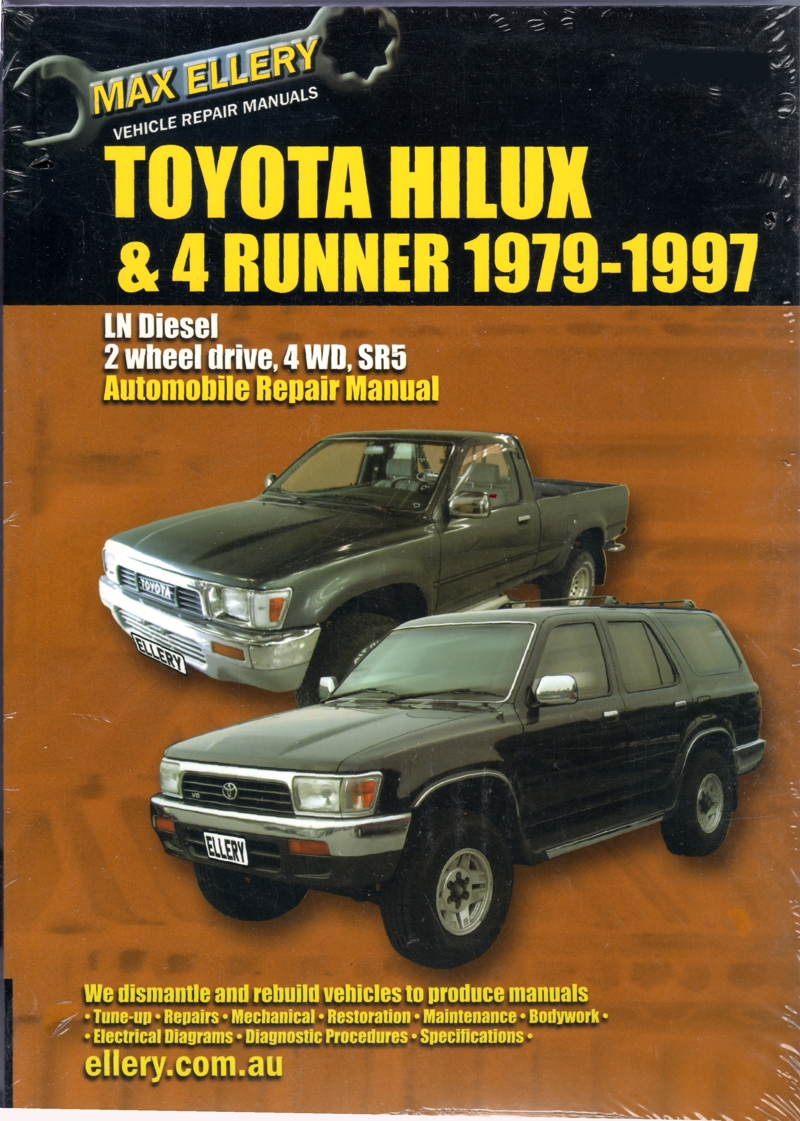

Toyota Hilux 4 Runner LN Series Diesel 1979-1997

NEW - softcover 408 pagesGet other Toyota Hi-Lux and 4Runner manuals click hereToyota Hilux/4 Runner (LN Series) Diesel 1979 - 1997 Owners Service & Repair Manual covers the Toyota Hilux and 4 Runner, 1977 to 1997, LN series, with diesel engine, 2 wheel drive and 4 wheel drive. Models covered: Contents: This Repair Manual is a comprehensive aftermarket source of technical information available. These workshop manuals are produced for the Australian market. The vehicle specifications may vary from those sold in other countries. Please be aware of these possible differences prior to using the data contained within.

|

The Hilux started production in March 1968 once the RN10 in short-wheelbase kind through a 1.5 L engine, creating 77 PS in Japanese markets spec. The adjustment to the system was enough for a reported 130 kilometres each hour top speeds. It was upgraded to a 1.6 L inline-four engine in February 1971.

In April 1969, a long-wheelbase version is added to the range. The short-wheelbase variation in addition carried on in manufacturing for most even more many years. The long-wheelbase variation wasn't in love with the us markets until 1972. The Hilux had been provided as an alternative to the Toyota Crown, Toyota Corona, and Toyota Corona Mark II depending pickups in Japan, while the top, Corona, and Corona level II are repositioned as passenger sedans.

Notwithstanding the name "Hilux", it in fact was a luxury automobile only if set alongside the Stout. The Hilux was engineered and assembled by Hino Motors to change the earlier automobile that the Hilux had been derived from, called the Briska in market beneath the bigger and older Stout -- it replaced the Stout totally in certain areas. For North American marketplace, the actual only real human anatomy design was a regular cab quick bed and all are rear-wheel drive. They made use of an average truck setup of A-arms and coil springs in front plus live axle with leaf springs in back. A four-speed manual transmission is standard.

The inline-four engine or straight-four motor is a type of internal combustion four cylinder engine along with four cylinders attached within a straight-line, or jet over the crankcase. The single-bank of cylinders can be focused in a choice of a vertical or an inclined-plane while using the pistons operating a standard crankshaft. In which it is predisposed, it really is occasionally called a slant-four. Within a requirements chart or when an acronym is employed, an inline-four motor are indexed often as I4 or L4.

The inline-four design is within perfect biggest balance and confers a degree of mechanical ease which makes it preferred for economic climate automobiles. However, despite their convenience, it suffers from a secondary imbalance which causes small oscillations in modest motors. These oscillations become more effective as system size and energy boost, and so the stronger machines utilized in bigger cars generally are far more complex styles with more than four cylinders.

These days most brands of four-cylinder machines for vehicles build the inline-four layout, with Subaru s flat-four system being fully a significant exception, so four-cylinder was similar to as well as a considerably widely used term than inline-four. The inline-four is considered the most common motor setup in contemporary vehicles, whilst the V6 system may be the 2nd most widely used. Into the late 2000s, with auto makers creating attempts to cut back emissions; and increase gasoline performance because of the large price of oil therefore the economic recession, the proportion of brand new automobiles sold in the U.S. with four-cylinder engines rose from 30 percent to 47 percentage between 2005 and 2008, particularly in mid-size motors in which a decreasing range buyers has chosen the V6 results solution.

Two-stroke diesel system operation is comparable to that petrol alternatives, except that fuel is certainly not mixed with environment before induction, and crankcase will not need a working part into the cycle. The standard two-stroke design relies upon a mechanically driven good displacement blower to charge the cylinders with air before compression and ignition. The charging procedure furthermore assists in expelling burning gases leftover from previous power swing.

The archetype associated with contemporary as a type of the two-stroke diesel may be the Detroit Diesel Series 71 motor, created by Charles F. "employer" Kettering along with his peers at General Motors organization in 1938, in which the blower pressurizes a chamber into the motor block this is certainly often referred to as the "air box". The Electro-Motive Diesel engine is employed once the prime mover in EMD diesel-electric locomotive, marine and fixed programs, and ended up being created by the exact same group, and is created to the exact same principle. However, an important enhancement built into more later EMD machines may be the mechanically-assisted turbo-compressor, which supplies charge atmosphere making use of technical support during beginning, and offers cost atmosphere utilizing an exhaust gas-driven turbine during normal operations---thereby offering real turbocharging and also enhancing the motor s energy production by at the very least 50 %.

Three English Electric

7SRL Diesel alternator sets becoming installed

the Saateni Power Section, Zanzibar 1955

Within a two-stroke diesel engine, because the cylinder s piston ways the underside dead-centre fatigue ports or valves tend to be established relieving almost all of the excess stress after which it a passageway amongst the air package plus the cylinder are established, permitting air flow into the cylinder. The air flow hits the rest of the burning gases from the cylinder---this may be the scavenging techniques. Once the piston passes through base centre and starts up, the passageway try sealed and compression commences, culminating in fuel injection and ignition. Refer to two-stroke diesel machines to get more step-by-step coverage of aspiration sort and supercharging of two-stroke diesel motors.

Ordinarily, the number of cylinders are employed in multiples of two, although numerous cylinders can be used so long as force on crankshaft is counterbalanced to avoid excessive vibration. The inline-six-cylinder design is one of prolific in light- to medium-duty motors, though smaller V8 and bigger inline-four displacement machines are typical. Small-capacity motors are four- or six-cylinder sort, with the four-cylinder becoming the most frequent type found in automotive uses. Five-cylinder diesel machines are also produced, being truly a compromise between your smooth running of the six-cylinder in addition to space-efficient proportions associated with four-cylinder. Diesel machines for small plant machinery, ships, tractors, generators and pumps might four, three or two-cylinder types, because of the single-cylinder diesel system remaining for light stationary jobs. Direct reversible two-stroke marine diesels require about three cylinders for dependable restarting forwards and reverse, while four-stroke diesels need at the very least six cylinders.

The want to improve diesel system s power-to-weight ratio produced a few book cylinder arrangements to extract most power from a offered capability. The uniflow opposed-piston engine uses two pistons in one cylinder utilizing the combustion cavity in the centre and petrol in- and outlets within finishes. This will make a comparatively lighter, powerful, swiftly run and economic motor ideal for use within aviation. An illustration could be the Junkers Jumo 204/205. The Napier Deltic engine, with three cylinders organized inside a triangular development, each containing two opposed pistons, the complete motor creating three crankshafts, is amongst the better known.

In May 1972, the 1973 design 12 months Hilux premiered given that RN20. A more comfortable indoor was specified and external updates. A 2.25 m "long sleep" is a choice for the first time in united states, although such a version was indeed available around the world since April 1969. This obtained the "RN25" chassis rule. The 2.0 liter 18R system became for sale in late 1973 in Japan besides, albeit best together with a three-speed automated transmission.

The Hilux had been drastically redesigned in 1975 to be larger and with enhanced standard products. In united states the latest version furthermore designed the introduction of the quite a bit bigger 20R engine and also the SR5 upscale trim bundle. A five-speed guide transmission became recommended. In North America, the Hilux name had been completely phased out in support of "vehicle" by that season, having become fallen from literature and advertising beginning in 1973.

The redesigned Hilux was introduced in August 1978, having 4WD variant launched in Jan 1979. The 4WD variant -- not offered with any motors smaller compared to the two-litre "18R" -- showcased some typically common tech using larger Toyota Land Cruiser. Production of the four-wheel drives ended in July 1983, many 2WD modifications proceeded in parallel with all the next generation. The L series diesel engine had been provided on 2WD variations from September 1979 plus the 4WD variations in March 1983. In Japan, the Hilux is joined with the brand new Toyota MasterAce, revealing burden carrying tasks, and offered at Toyota Store stores alongside the Hilux.

In united states the Hilux spotted the usage four-wheel drive. They had a solid front axle and leaf suspension system. The human body saw a redesign that included single circular headlights and a less complex human body. This latest 4WD setup featured a gear-driven RF1A transfer case. This transfer case is unique in that their low-range decrease section is replicated, utilizing what some reference as a double or triple transfer circumstances. This results in a reduced overall gear ratio. It had been 1st Hilux offered by having an automatic transmission.

In 1981 a vehicle developing agreement was established between Toyota, Winnebago companies as well as 2 various other aftermarket customizers. It was allowing Toyota to enter the SUV marketplace in the united states. The vehicles which resulted from this collaboration are the Trekker, Wolverine, and also the Trailblazer. All three used the Hilux 44 RV taxi and chassis, as well as an all-fiberglass backside area. There were at the least 1,500 Trekkers, 400 Trailblazers plus an unidentified quantity of Wolverines marketed in the united states. Analysis and developing run the Trekker led to the introduction of the 4Runner/Hilux browse, that has been introduced in 1984.

Toward the termination of the SR5 s manufacturing run, Toyota introduced the blissful luxury Mojave when it comes to people markets as being a limited-production model with choices not available on virtually any Toyota pickup. List priced at US,308, it showcased container seats, two-speaker multiplex broadcast, chrome front side and back bumpers, no Toyota logo design on either the grille or tailgate. Cruise controls, energy steering, and ac had been recommended. It had been run on the SR5 s standard 2.4 L inline four.

The August 1983 redesign launched the Xtracab, two-row prolonged cab choice. These "1984" versions carried on the carbureted 22R system while design season 1984 furthermore spotted the development of the gasoline injected 22R-E. Two diesel engines were additionally offered, the 2L and the turbocharged 2L-T. The diesels had been stopped in the U.S. following the 1986 design season, this is due to greater efficiency expectations from subscribers plus the wide availability of affordable gas. Another seasons saw the introduction of a turbocharged choice, the 22R-TE, possibly considering increasing competition from Nissan who already supplied a V6 vehicle at the moment. The solid front axle was swapped for the separate front side suspension/torsion bar setup within the 44 design in 1986, and recommended automatic differential disconnect for the front differential and an digital transfer situation was added aswell. A V6 motor ended up being launched in 1988. The Hilux-based 4Runner which made their entry in Australian Continent, the united states additionally the great britain was according to this generation Hilux; in a few various other areas, like Japan, it was known as the Hilux Surf.

Toyota introduced an innovative new generation associated with Hilux in most markets in late 1988 nevertheless the fourth generation remained in production until 1997 in Southern Africa. Toyota states it was as a result of South African "content rules" which made it cheaper to continue to make the fourth generation Hilux, in the place of to retool the plant when it comes to 5th generation.

Drum brake system are utilized generally in most durable trucks, some moderate and lighter task vehicles, and few vehicles, soil bicycles, and ATVs. Drum brake system are often applied to the rear tires since almost all of the stopping force try produced because of the forward brake system associated with vehicle and then the heat created within the back was much less. Drum brake system let simple incorporation of the parking braking system.

Drum brakes may also be sporadically fitted because the parking braking system even when the trunk rims use disc brakes whilst the primary brake system. Numerous rear disk braking techniques make use of a parking braking system when the piston in the caliper are actuated by a cam or screw. This compresses the pads contrary to the rotor. But this kind of system becomes a whole lot more stressful if the back disk brake system incorporate fixed, multi-piston calipers. Within circumstance, a little drum is normally fitted within or within the braking system disk. This particular brake can also be referred to as a banksia brake.

In hybrid car programs, put on in stopping systems try considerably reduced by energy recuperating motor-generators, therefore some hybrid automobiles like the GMC Yukon crossbreed and Toyota Prius utilize drum brake system.

Disk brake system depend on pliability of caliper seals and minor runout to discharge pads, leading to drag, gasoline mileage loss, and disk scoring. Drum brake return springs provide much more positive action and, adjusted properly, frequently have less drag whenever revealed. Its but possible to create unique seals that retract the piston for a disc brake.

Certain heavy responsibility drum braking system systems compensate for burden whenever deciding wheel cylinder pressure; an element uncommon when discs are employed. One particular automobile is the Jeep Comanche. The Comanche can automatically submit more force to your back drums according to the size of the load. Almost every other companies purchased burden sensing valves inside hydraulics toward rear axle for a long time.

Due to the fact that a drum braking system s friction communications location is at the circumference associated with braking system, a drum braking system can provide more stopping power than the same diameter disk brake. The enhanced friction contact section of drum braking system shoes on the drum permits drum braking system footwear to last for a longer time than disc braking system shields found in a brake system of close proportions and braking energy. Drum brake system retain temperatures and so are more complex than disc brakes but they are usually the less expensive and powerful braking system kind to use in back brake programs as a result of the low temperatures generation of back brakes, a drum brake s self-applying nature, larger rubbing surface email room, and endurance use faculties.

To listing advantages of drum brake system:

cheaper to keep. The sole replacement part ended up being often the footwear at around /wheel in the place of shields, rotors and calipers at 0/wheel

lower frequency of maintenance. Drums didn t corrode unlike disks

more environmentally friendly due to 1 and 2 and used footwear made a return credit unlike pads and rotors so little ended up being scrapped.

less dangerous since no surprises from wet brakes. Disk brake system are exposed to liquid

self energizing resulting from a refined design feature at no extra expense.

Wheel cylinders were simple to recondition by the owner unlike calipers.

Drums are lighter than disks, wheel cylinders a great deal light than calipers

less costly to create

The following redesign, in 1988, produced a longer-wheelbase option, 3,099 mm in the place of 2,616 mm when it comes to regular wheelbase. Their one-piece cargo-box wall space removed the rust-prone seams that were present earlier versions. The V6 Xtracab SR5 acquired Motor Trend magazine s vehicle of the season award that year. The Xtracabs now featured most place behind leading chairs compared to the final generation which let optional jump-seats for back people, an attribute most consistent with competitors of that time.

In 1991, United states production began within NUMMI plant in Fremont, California, but some vehicles marketed in the us during 91--95 design ages were still manufactured in Japan.

The Hilux gotten a small renovation in 1991, which was a grill change therefore the latest Toyota emblem that were recently adopted.

It absolutely was in this generation that Toyota discontinued the Hilux in america, changing it with all the brand new Tacoma in 1995.

The benefit of a limited-slip differential try demonstrated by thinking about the instance of the standard differential in off-roading or snowfall situations in which one wheel starts to fall or shed experience of the ground. In such a case through a standard differential, the falling or non-contacting wheel will get most of the power, whilst the contacting wheel will stay fixed with the ground. The torque transmitted will be equal at both tires, and therefore, will not go beyond the threshold of torque needed to go the wheel with grip. Within situation, a limited-slip differential stops exorbitant energy from being assigned to one wheel, and thus keeping both rims in powered rotation.

While manufacturing vehicles with off-road effectiveness can travel on unsurfaced roadways, customizations are needed to travel on terrains surpassing capabilities of initial configuration. Listed below are a number of alterations designed for off-roading.

Automobile lifts

A vehicle lift occurs when the automobile try lifted to improve the quantity of clearance between the crushed therefore the base associated with the body or framework of this automobile. A lift will also help with tire clearance whenever going over large obstacles with only one or 2 wheels and enable the vehicles differential to flex with out the tires rub the insides associated with the fenders. There are lots of options for vehicle raise. Some means may be blended collectively to better fit the requirements.

Human body lift

This may be a process this is certainly just usable on human anatomy -on-frame design found in some pickups plus some SUVs. A human anatomy lift is performed by placed spacers between the standard mounting points for the car s chassis and the body. These usually become between 1--4 inches. More than four ins can establish a less sturdy setup. Increasing your body allows the fitting of over-sized tires.

Suspension raise

suspension system lift actually modification to car s suspension system including springs, surprise absorbers, controlling arms and steering linkage to boost the level.

Huge tires

Increasing the tire dimensions advances the ground approval of all components of car like suspended components, for instance the axles. . They possibly necessary to render changes to car s suspension system or body with regards to the measurements of the tires to be installed and also the specific vehicle.

Axle raise

Portal axles, a kind of axles utilizing the axle range above the surface allows increasing the floor approval at differential matters without corresponding increase in total car level and/or center of gravity.

Traction

Push train

The drive-train traits decide the allocation of torque delivery from transmission every single driven axle end because their available grip modification.

Some grip control equipment made use of is:

Locking differential

Limited-slip differential

Four-wheel drive

A vehicle with two drive tires has the issue that whenever they converts a corner the drive rims must turn at different rates to maintain traction. The automotive differential is designed to push a set of rims while letting them rotate at different rates. In vehicles without a differential, such as for example karts, both operating wheels is forced to turn at the same speed, usually for a typical axle driven by a easy chain-drive method.

When cornering the internal wheel journeys a shorter length than the exterior wheel, therefore without any differential either the inner wheel rotates too fast or even the exterior wheel drags, which results in tough and volatile handling, damage to tires and roadways, and pressure on the whole drivetrain.

In rear-wheel drive vehicles the central drive shaft engages the differential through the hypoid equipment the crown-wheel is mounted on the provider of this planetary string that sorts the differential. This hypoid gear actually bevel gear that adjustment the way for the drive rotation.

One unwanted effect of a mainstream differential is the fact that it may restrict grip under less than ideal circumstances. The quantity of grip necessary to propel the automobile at a moment depends on force at that instant---how heavy the car was, simply how much drag and rubbing there was, the gradient for the roadway, the automobile s energy, an such like.

The torque applied to each driving-wheel is because the engine, transmission and drive axles applying a twisting energy from the opposition associated with the grip at that roadwheel. In reduced gears and so at lower rates, and unless the load try remarkably high, the drivetrain can supply as much torque as necessary, so that the restricting factor becomes the grip under each wheel. Therefore convenient to define traction due to the fact amount of torque that may be produced involving the tire and also the roadway area, ahead of the wheel starts to fall. If torque applied to one of the drive wheels surpasses the threshold of grip, then that wheel will twist, and therefore just create torque at each other driven wheel tied to the sliding friction within slipping wheel. The lower nett traction may still be enough to propel the vehicle.

Vehicle stopping system fade, or braking system fade, could be the reduction in preventing energy that may take place after recurring or sustained application regarding the brakes, especially in high burden or high-speed problems. Braking system fade can be quite a factor in any car that utilizes a friction stopping program including vehicles, trucks, motorcycles, airplanes, and bikes.

Brake fade was the effect of a buildup of heat into the braking surfaces in addition to subsequent adjustment and reactions into the brake program components and can become experienced with both drum brake system and disc brake system. Loss in preventing power, or fade, can be caused by friction fade, mechanical fade, or fluid fade. Brake fade is significantly reduced by proper products and content build and selection, including close cooling.

Braking system fade happens oftentimes during powerful driving or when heading down a lengthy, high slope. Its more predominant in drum brakes because of their setup. Disc brakes are a lot most resistant to braking system fade because the heat could be ventilated out of the rotor and pads easier, and also turned out to be a typical function in front brake system for the majority of automobiles.

Braking system bleeding could be the procedure performed on hydraulic brake systems wherein the brake outlines is purged of every air bubbles. This is certainly needed because, whilst braking system fluid is an incompressible fluid, atmosphere bubbles were compressible fuel and their particular existence inside braking system system considerably decreases the hydraulic stress that can be created in the program. The exact same practices utilized for bleeding may also be used for purging, where old fluid are replaced with brand-new fluid, that is necessary repair.

The braking system liquid ability of a typical automobile is just about 500ml. Brake fluid was poisonous, and needs to be managed carefully and discarded properly. More vehicles incorporate DOT a few Brake liquids, that might be combined, but DOT 5 is silicone polymer centered and never compatible with DOT three or four. Most kinds of braking system fluid harm automotive paint and plastic materials on contact, so unique attention must be taken when working with this liquid: any spills must certanly be immediately washed up. Braking system liquid try water soluble so that it are rinsed off with liquid.

The process is carried out by pushing clean, bubble-free braking system substance through the entire system, typically from master cylinder into calipers of disc brake system, but in specific matters when you look at the contrary movement. A braking system bleed screw is normally installed within greatest point on each cylinder or caliper.

Listed here information of brake bleeding method is intended and then offer an overview of the common methods, and is to not be properly used as specific training. The procedure differs from a automobile to another together with manufacturers store handbook process is put.

You will find five biggest types of hemorrhaging: Pump & Hold, cleaner, stress, Bench, and Reverse. Pump & Hold typically requires two people, another techniques can be carried out by way of a solitary individual.

Pump and Hold Process, a couple: someone pumps the braking system pedal to compress air, after that holds pressure about it. The other person opens up the bleeder device to let away liquid and atmosphere, then closes the device following the pedal features landed. The process is duplicated, frequently many times, for every single wheel. Typically a length of clear tubing are connected to the bleeder device and run to a container throughout the process, both to get the harmful braking system liquid and much better see the fluid and bubbles. The master cylinder reservoir should be replenished frequently, for if it goes dry the complete techniques must be redone. The cover must be kept free so that the liquid may be attracted, but is set up so substance cannot squirt from the return stroke. A block could be placed directly under the pedal such that it does not bottom aside in this procedure, while the master cylinder seals could possibly be damaged by experiencing accumulated deposit and deterioration.

Pump and Hold technique, anyone choice: This uses whether "one man" bleeder means, consisting of a single method device at the conclusion of a period of tubing that will be attached to the bleeder device, or even a special a good way bleeder device. These processes possess drawback that air may also be drawn back in the system via the bleeder valve threads, this is alleviated to a level by making use of Teflon tape on those threads. This method isn't advised because with just one person it is impossible to confirm if certainly the fluid this is certainly taken from the bleeder valve have any atmosphere provide, such as coming from a bad master cylinder or improper/incomplete bleeding.

Vacuum cleaner means: The master cylinder is topped down together with address kept free. A specialized vacuum cleaner pump is connected to the bleeder valve, which will be established and liquid extracted with all the pump until it works free from bubbles. Once more, the master cylinder reservoir degree needs to be maintained. The vacuum cleaner technique also can lure air through the bleeder threads, therefore the bubbles won't ever clear. However, this doesn't mean there's nonetheless environment in the braking system lines. Making use of Teflon tape regarding bleeder threads will alleviate this problem and permit that accurately establish if you have evacuated all air from the system.

Pressure Method: A specific force pump, was attached to the master cylinder and full of liquid. The pump is used to pressurize the device to about 10psi, together with bleeder valves become unsealed individually before the substance is obvious of environment. One benefit to this system is the fact that pump reservoir frequently keeps sufficient fluid that working dry isn't likely. This is basically the technique most professional stores utilize.

Reverse technique: In this process, a pump is employed to make liquid through the bleeder valve to the master cylinder. This technique may have advantages in many cases, nonetheless it isn't in common use.

The order in which the tires tend to be bled try specified when you look at the specific automobile s store manual. Typically the wheel farthest from the master cylinder is performed initially, employed toward the nearest wheel last.

If bleeding brake system as a result of master cylinder substitution the master cylinder is usually "bench bled" before set up. Usually by securing they regarding the bench, filling they with liquid, connecting accessories and hoses to route substance from socket ports on the master cylinder back to their reservoir, and continuously depressing the master cylinder plunger until bubbles are no much longer observed coming from the hoses.

Toyota Hilux/4 Runner Diesel Owners solution, Workshop and restoration Manual1979 - 1997 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996

0 Items (Empty)

0 Items (Empty)

>

>