Login to enhance your online experience. Login or Create an Account

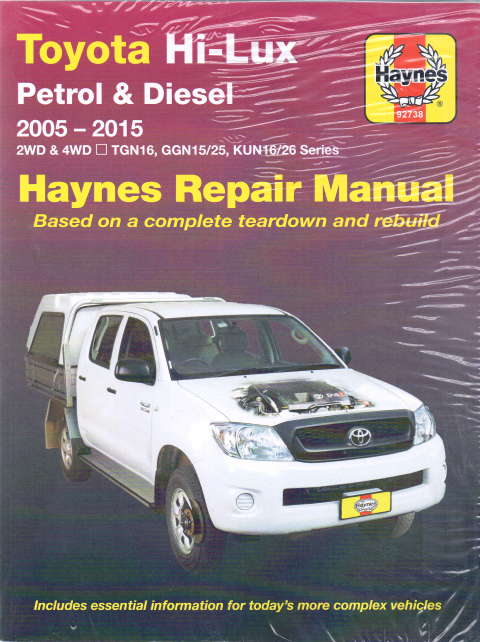

Toyota Hi-Lux Petrol and Diesel 2WD and 4WD 2005 - 2015 Haynes repair workshop manual NEW

|

NEW - softcover Toyota Hi-Lux Petrol & Diesel 4WD & 2WD 2005 - 2015 Haynes Owners Service & Repair Manual covers 2WD and 4WD, Petrol and Diesel versions of the seventh generation Toyota Hilux released in Australia in March 2005. Series Covered: * TGN16, GGN15, KUN16, 2 Wheel Drive * GGN25, KUN26 4 Wheel Drive Petrol Engines Covered: * 2.7 litre (2694cc) '2TR-FE' VVT-i DOHC 4 Cylinder * 4.0 litre (3956cc) '1GR-FE' VVT-i DOHC V6 Diesel Engine Covered: * 3.0 litre (2982cc) '1KD-KTV' D-4D DOHC Common-Rail, Direct Injection 4 Cylinder Turbo Diesel Contents: * Introductory Pages About this Manual; Introduction to the Toyota Hi-Lux; Vehicle Identification Numbers; Buying Parts; Maintenance Techniques, Tools and Working Facilities; Booster Battery (jump) starting; Jacking and Towing; Automotive Chemicals and Lubricants; Conversion Factors; Safety First!; Troubleshooting * Routine Maintenance * 2.7 litre 4 Cylinder Petrol Engine * 4.0 litre V6 Petrol Engine * 3.0 litre 4 Cylinder Diesel Engine * General Engine Overhaul Procedures * Cooling, Heating and Air Conditioning * Fuel and Exhaust Systems - Petrol Engines * Fuel and Exhaust Systems - Diesel Engines * Charging and Starting Systems * Emissions & Engine Control Systems * Manual Transmission * Automatic Transmission * Transfer Case * Clutch and Driveline * Brakes * Suspension and Steering Systems * Body * Chassis Electrical System * Wiring Diagrams NOTE: Only maintenance, adjustment, minor repair procedures plus removal and installation are described for the Automatic Transmission. |

Turbo-diesel, moreover created because turbodiesel plus turbo diesel pertains with any diesel engine loaded with a turbocharger. Turbocharging is prevalent inside contemporary vehicle plus truck diesel motors with make high energy outputs, lower emissions degrees, plus improved efficiency from a synonymous ability of engine. Turbo-diesels inside cars provide a high refinement degrees than their naturally aspirated counterparts.

A turbocharger, or turbo, is a turbine-driven forced induction device which increases an engine s efficiency plus force by forcing additional air into the combustion room. This improvement over a naturally aspirated engine s output results considering the turbine will force more air, plus proportionately more gas, into the combustion room than atmospheric stress alone.

Turbochargers were initially termed as turbosuperchargers whenever all forced induction equipment were categorized because superchargers. Nowadays the expression "supercharger" is generally used with just mechanically driven forced induction equipment. The key difference between a turbocharger along with a traditional supercharger is the fact that the latter is mechanically driven by the engine, usually from the belt associated with the crankshaft, while a turbocharger is driven with a turbine driven by the engine s exhaust fuel. Compared with a mechanically driven supercharger, turbochargers are better, yet less sensitive. Twincharger pertains with an engine with both a supercharger along with a turbocharger.

Turbochargers are popular about truck, auto, train, aircraft, plus construction equipment machines. These are generally usually utilized with Otto cycle plus Diesel cycle internal combustion motors. They have additionally been found valuable inside automotive gas cells.

The turbocharger was invented inside the early 20th century by Alfred Bchi, a Swiss engineer as well as the head of diesel engine analysis at Gebruder Sulzer engine production organization inside Winterthur. Bchi particularly intended his device with be utilized about diesel motors. His patent of 1905 noted the efficiency improvements a turbocharger can bring with diesel machines that inside 1922 had initially been developed for employ inside road transportation.

At the time, metal plus bearing technologies wasn't sufficiently advanced with permit a useful turbocharger with be built. The initial useful turbodiesels were sea motors fitted with 2 German passenger liners - the Danzig as well as the Preussen inside 1923, every having 2 10-cylinder machines of 2,500 horsepower. By the late 1920s, many diesel engine builders were generating big turbodiesels for sea plus stationary employ, including Sulzer Bros., MAN, Daimler-Benz, plus Paxman.

Turbocharger technologies was improved greatly by developments throughout World War II plus next development of the fuel turbine. It was today potential with utilize small turbochargers about small, higher-speed motors. Diesel locomotives with turbodiesels started appearing inside the late 1940s plus 1950s.

In 1951 MAN presented a turbocharged variation of their MK26 truck, though it was not place into mass manufacturing. Series creation of turbocharged diesel pickups commenced inside 1954, whenever both MAN 750TL1 plus Volvo Titan Turbo were introduced with the markets. The building of the Interstate Highway System inside the USA from 1956 created long-distance road transportation of goods more appealing. To maintain with general traffic, more effective machines came inside improving need. Cummins, Detroit, plus CAT all had turbo-charging because a choice by the late-1960s. In Europe, legislation was introduced inside Germany mandating a minimal power-to-weight ratio for trucks; by the late 1960s, a 38-tonne comprise had with have at minimum 304 hp. Many producers met these requirement with large-displacement all-natural aspiration machines, several with all the way of large-displacement or turbo-charging, whilst Scania plus Volvo where amidst those which just offered turbocharged pickups which met the demands. Turbo-charging wasn't preferred initially because the motors were perceived with be less reliable, yet the way claimed a decisive victory by the mid-1970s because the 1973 oil crisis improved gas fees. The last marketplace to find the absolute penetration of turbo diesels was Japan, where legislation about particle emissions effectively mandated all-natural aspiration machines till efficient particle filters became accessible.

Experiments with small turbodiesels of the size right for a vehicle were carried out inside the 1960s. The Rover Company built experimental 2.5 liter 4-cylinder turbodiesels inside 1963, however didn't place the shape into creation. The initially turbodiesel creation automobile was the Mercedes-Benz 300SD, introduced inside May 1978. It utilized a Garrett AiResearch turbocharger, plus was yielded just for the United States. In Europe, the initial turbodiesel was the Peugeot 604 inside early 1979. Turbodiesel vehicles started with be commonly built plus available inside Europe throughout the late 1980s plus early 1990s, a trend which has continued with the modern. In France, due with a taxes structure that gave turbodiesels a comparative benefit, sales shot up earlier, achieving 33,000 passenger auto sales inside 1983.

On the other hand with turbochargers, superchargers are mechanically driven by the engine. Belts, stores, shafts, plus gears are prevalent techniques of powering a supercharger, placing a mechanical weight found on the engine. For instance, found on the single-stage single-speed supercharged Rolls-Royce Merlin engine, the supercharger utilizes regarding 150 horsepower. Yet the pros outweigh the costs; for the 150 hp with drive the supercharger the engine generates an more 400 horsepower, a web gain of 250 hp. This really is where the main downside of the supercharger becomes apparent; the engine should withstand the internet force output of the engine and the force with drive the supercharger.

Another downside of several superchargers is lower adiabatic efficiency than turbochargers. Adiabatic efficiency is a measure of the compressor s ability with compress air without adding extra heat to this air. Even beneath perfect conditions, the compression procedure usually results inside elevated output temperature; nevertheless, better compressors provide less extra heat. Roots superchargers impart more heat with the air than turbochargers. So, for a provided amount plus stress of air, the turbocharged air is cooler, plus because a outcome denser, containing more oxygen molecules, plus consequently more possible force than the supercharged air. In useful application the disparity amongst the 2 is dramatic, with turbochargers usually producing 15% with 30% more energy based entirely found on the variations inside adiabatic efficiency.

By comparison, a turbocharger refuses to spot a direct mechanical weight found on the engine, though turbochargers put exhaust back stress about motors, improving pumping losses. This really is better, considering whilst the improved back stress taxes the piston exhaust stroke, much of the power driving the turbine is offered by the still-expanding exhaust fuel which might otherwise be wasted because heat from the tailpipe. On the other hand to supercharging, the main downside of turbocharging is what exactly is called "lag" or "spool time". This really is the time amongst the need for an heighten inside force as well as the turbocharger providing improved intake stress, plus therefore improved force.

Throttle lag happens considering turbochargers depend found on the buildup of exhaust fuel stress with drive the turbine. In varying output systems including vehicle motors, exhaust fuel stress at idle, low engine speeds, or low throttle is normally insufficient with drive the turbine. Just whenever the engine reaches enough speed does the turbine section begin with spool up, or angle swiftly enough with provide intake stress above atmospheric stress.

A mixture of an exhaust-driven turbocharger plus an engine-driven supercharger may mitigate the weaknesses of both. This technique is known as twincharging.

In the case of Electro-Motive Diesel s two-stroke motors, the mechanically-assisted turbocharger is not especially a twincharger, because the engine utilizes the mechanical assistance with charge air just at lower engine speeds plus business. When above notch # 5, the engine utilizes true turbocharging. This differs from a turbocharger which utilizes the compressor section of the turbo-compressor just throughout beginning plus, because a two-stroke motors cannot naturally aspirate, plus, according with SAE definitions, a two-stroke engine with a mechanically-assisted compressor throughout idle plus low throttle is considered naturally aspirated.

Improvements inside force, gas economy, plus Noise, Vibration, plus Harshness inside both small- plus large-capacity turbodiesels over the last decade have spurred their popular adoption inside certain markets, notably inside Europe where they create up over 50% of modern vehicle registrations. Turbodiesels are considered more flexible for automotive uses than naturally aspirated diesels, that have sturdy low-speed torque outputs nevertheless shortage force at high speeds. Turbodiesels is tailored with have a more acceptable spread of both energy plus torque over their speed range or, when being built for commercial utilize, is tailored with better either torque or force at a provided speed depending found on the actual utilize. Naturally aspirated diesels, virtually without exception, have a lower force output than a petrol engine of the same capability while the same time requiring stronger internal components including the pistons plus crankshaft with withstand the better stresses of the diesel engine s running cycle. These factors provide naturally aspirated diesels a bad power-to-weight ratio. Turbocharger units weigh extremely small yet may provide immense energy, torque, plus efficiency improvements. Fitting a turbocharger could bring a diesel engine s power-to-weight ratio about the same level because an equal petrol device, generating turbodiesels desirable for automotive utilize, where producers aim for similar force outputs plus handling properties over their range, irrespective of the kind of force device selected.

A Mazda3 with a contemporary well-known rail 1.6 liter turbodiesel engine with varying geometry turbocharger, intercooler, 16 valves, double overhead camshafts plus piezo controlled 7-stage direct injection.

Turbochargers are inside several techniques more suited with procedure inside diesel motors. The small speed range which Diesel motors function inside mean which the turbocharger has with change speed less, reducing turbo lag plus improving efficiency. Diesel motors never need dump valves. Perhaps many greatly, the diesel engine is immune with detonation considering the gas is not injected till when of combustion. So, the compression ratio refuses to need to be reduced, or alternative anti-detonation measures taken, because will be needed for a turbocharged spark-ignition engine. The turbodiesel engine will equally assist with all the amount of torque it can provide out. Commonly employed inside pickups, it assists boost the towing ability of the truck, and also gas economy.

During the 1990s, turbodiesel machines were primarily employed inside the United States for light pickups. An illustration is the Ford Power Stroke engine series, installed about Ford F-Series Super Duty pickup pickups, the E-series vans as well as the Excursion sport utility cars. In 1989, Dodge began generating light duty pickups with 5.9 liter turbo-diesel engine.

As need for diesel motors inside standard sedan plus station wagon vehicles inside the United States has been much lower than inside saloon plus property vehicles inside Europe, the development of small automotive turbodiesels has been led by European producers inside latest years. Diesel gas inside the USA had a greatly high amount of sulphur than the gas selected inside Europe, that meant which diesel-engined vehicles from European machines had with either be fitted with specifically developed gas plus emissions control program for the North American marketplace, or couldn't be available because marketplace.

After ultra low sulphur diesel was introduced inside the United States inside October 2006, automakers started to provide turbodiesel models that may take benefit of it with minimize emissions. Manufacturers including Volkswagen, BMW, Audi, plus Mercedes-Benz have been releasing vehicles with 4 plus six-cylinder turbodiesels.

Availability of turbodiesel models improved inside the 2014 model year, because a limited more producers introduced passenger vehicles plus sport utility cars driven by turbodiesel motors. GM started marketing the 2014 Chevrolet Cruze Clean Turbo Diesel inside 2013. The Mazda6 fitted with all the SKYACTIV-D engine is obtainable in the late spring of 2014. The 2014 Jeep Grand Cherokee with all the 3.0L EcoDiesel V6 engine is accessible at the finish of 2013. Additionally, producers have began advertising vans plus light-duty pickups with turbodiesels again. The 2014 Ram 1500 is accessible with all the EcoDiesel engine inside March 2014. The 2015 Ford Transit van, with a 3.2L I-5 Power Stroke turbodiesel way, is obtainable in the summer of 2014. The next-generation Nissan Titan pickup truck, expected with be obtainable in 2014, can have a Cummins-sourced turbodiesel available

An Injection Pump is the device which pumps gas into the cylinders of the diesel engine. Traditionally, the injection pump is driven indirectly within the crankshaft by gears, stores or perhaps a toothed belt which moreover forces the camshaft. It rotates at half crankshaft speed inside a traditional four-stroke engine. Its timing is these which the gas is injected just rather somewhat before top dead centre of which cylinder s compression stroke. It is equally widespread for the pump belt about gasoline motors with be driven straight within the camshaft. In certain systems injection pressures is because significant because 210 MPa.

Earlier diesel pumps selected an in-line design with a series of cam-operated injection cylinders inside a line, very like a miniature inline engine. The pistons have a continual stroke amount, plus injection amount is controlled by rotating the cylinders against a cut-off port which aligns with a helical slot inside the cylinder. Whenever all cylinders are rotated at when, they simultaneously differ their injection amount with provide almost energy within the engine. Inline pumps nonetheless discover favour about big multi-cylinder motors like those about pickups, construction plant, static motors plus agricultural cars.

Distributor diesel injection pump

For employ about vehicles plus light pickups, the rotary pump or distributor pump was developed. It utilizes a single injection cylinder driven from an axial cam plate, that injects into the individual gas lines through a rotary distribution valve. Later incarnations including the Bosch VE pump fluctuate the injection timing with crank speed with let better force at excellent crank speeds, plus smoother, more affordable running at slower revs. Many VE variants have a pressure-based program which enables the injection amount with strengthen over general with let a turbocharger or supercharger prepared engine with develop more energy below boost conditions.

Inline diesel metering pump

All injection pumps include the governor with cut gas provide when the crank speed endangers the engine - the thick moving components of diesel machines never tolerate overspeeding perfectly, plus catastrophic damage may happen when they are over-revved. Poorly maintained plus used machines could consume their lubrication oil by used out crankcase ventilation systems plus run away , causing improving engine speed till the engine destroys itself. This really is considering many diesel motors just control their speed by gas provide control plus don t have a throttle valve with control air consumption.

Common rail direct gas injection is a contemporary variant of direct gas injection program for petrol plus diesel machines.

On diesel machines, it qualities a high-pressure gas rail feeding individual solenoid valves, because opposed with low-pressure gas pump feeding device injectors. Third-generation normal rail diesels today feature piezoelectric injectors for improved precision, with gas pressures as much as 3,000 bar.

Solenoid or piezoelectric valves create potential fine electronic control over the gas injection time plus amount, as well as the high stress which the normal rail technologies makes accessible delivers greater gas atomisation. To lower engine sound, the engine s electronic control device may inject a tiny amount of diesel before the principal injection event, therefore reducing its explosiveness plus vibration, and also optimising injection timing plus amount for variations inside gas standard, cold beginning and so forth. Some advanced usual rail gas systems work because various because five injections per stroke.

Common rail motors need the fairly brief with no heating-up time, depending about ambient temperature, plus provide lower engine sound plus emissions than elder systems.

Diesel machines have historically chosen numerous types of gas injection. Two prevalent kinds include the device injection program as well as the distributor/inline pump systems. While these elder systems offered exact gas amount plus injection timing control, they were limited by many factors:

They were cam driven, plus injection stress was proportional with engine speed. This usually meant which the greatest injection stress can just be attained at the greatest engine speed as well as the maximum achievable injection stress reduced because engine speed reduced. This relationship is true with all pumps, even those selected about popular rail systems. With device or distributor systems, the injection stress is linked with the instant stress of the single pumping event without accumulator, and therefore the relationship is much more prominent plus troublesome.

They were limited inside the amount plus timing of injection occasions which may be commanded throughout a single combustion event. While numerous injection occasions are potential with these elder systems, it's more difficult plus costly with achieve.

For the typical distributor/inline program, the begin of injection happened at a pre-determined stress plus ended at a pre-determined stress. This characteristic resulted from "dummy" injectors inside the cylinder head that opened plus shut at pressures determined by the spring preload used with the plunger inside the injector. When the stress inside the injector reached a pre-determined level, the plunger might lift plus injection might begin.

In popular rail systems, a high-pressure pump shops a reservoir of gas at excellent stress --- about plus above 2,000 bars. The expression "popular rail" pertains with the truth which the gas injectors are provided with a popular gas rail that is nothing over a stress accumulator where the gas is stored at excellent stress. This accumulator supplies numerous gas injectors with high-pressure gas. This simplifies the cause of the high-pressure pump because it just must keep the commanded stress at a target. The gas injectors are usually ECU-controlled. Whenever the gas injectors are electrically triggered, a hydraulic valve is mechanically or hydraulically opened plus gas is sprayed into the cylinders at the desired stress. Because the gas stress power is stored remotely as well as the injectors are electrically actuated, the injection stress at the begin plus end of injection is especially close to the stress inside the accumulator, therefore producing a square injection rate. If the accumulator, pump plus plumbing are sized correctly, the injection stress plus rate is the same for every of the several injection occasions.

The TDI engine utilizes direct injection, where a gas injector sprays atomised gas straight into the key combustion room of every cylinder, instead of the pre-combustion room common inside elder diesels that utilized indirect injection. The engine additionally utilizes forced induction through a turbocharger with strengthen the amount of air that is capable with enter the engine cylinders, plus many TDI machines furthermore feature an intercooler with lower the temperature of the charged , or compressed air within the turbo, therefore improving the amount of gas which is injected plus combusted. These, in combination, let for better engine efficiency, plus consequently better force outputs, when furthermore decreasing emissions plus providing more torque than the non-turbo plus non-direct injection petrol engined counterpart from VAG.

Similar technologies has been employed by additional automotive firms, yet "TDI" especially pertains with these Volkswagen Group machines. Naturally aspirated direct-injection diesel machines prepared by Volkswagen Group employ the Suction Diesel Injection label.

Because these machines are comparatively low displacement plus very compact they have a low surface location. The resulting reduced surface location of the direct injection diesel engine reduces heat losses, plus therefore increases engine efficiency, at the cost of somewhat improved combustion sound. A direct injection engine is furthermore simpler with commence whenever cold, due to better placing plus use of glowplugs.

Direct injection turbodiesel machines are frequent winners of numerous prizes inside the International Engine of the Year Awards. In 1999 inside certain, six from twelve categories were claimed by direct injection engines: 3 were Volkswagen, 2 were BMW, plus 1 Audi. Notably which year, the Volkswagen Group 1.2 TDI 3L beat the Toyota Prius with win "Best Fuel Economy" inside its class. The TDI engine has earned "Green Car of the Year award" inside the years 2009 plus 2010 whipping alternative numerous electrical vehicles.

Turbocharger lag is the time necessary with change force output inside reaction with a throttle change, observed because a hesitation or slowed throttle reaction whenever accelerating than a naturally aspirated engine. This really is due with the time required for the exhaust program plus turbocharger to create the necessary boost. Inertia, friction, plus compressor weight are the main contributors with turbocharger lag. Superchargers never suffer this condition, considering the turbine is eliminated due with the compressor being straight driven by the engine.

Turbocharger applications is classified into those which need changes inside output force plus those which never. While significant with differing levels, turbocharger lag is many challenging inside applications which need fast changes inside force output. Engine designs lessen lag inside a quantity of ways:

Lowering the rotational inertia of the turbocharger by utilizing lower radius components plus ceramic plus additional lighter materials

Changing the turbine s aspect ratio

Increasing upper-deck air stress plus improving wastegate response

Reducing bearing frictional losses, e.g., utilizing a foil bearing instead of a traditional oil bearing

With variable-nozzle or twin-scroll turbochargers

Decreasing the amount of the upper-deck piping

Utilizing several turbochargers sequentially or inside parallel

Utilizing an antilag system

Utilizing a turbocharger spool valve with heighten exhaust fuel flow speed with the turbine

A turbocharger, or turbo, is a turbine-driven forced induction device which increases an engine s efficiency plus force by forcing additional air into the combustion room. This improvement over a naturally aspirated engine s output results considering the turbine will force more air, plus proportionately more gas, into the combustion room than atmospheric stress alone.

Turbochargers were initially termed as turbosuperchargers whenever all forced induction equipment were categorized because superchargers. Nowadays the expression "supercharger" is generally used with just mechanically driven forced induction equipment. The key difference between a turbocharger along with a traditional supercharger is the fact that the latter is mechanically driven by the engine, usually from the belt associated with the crankshaft, while a turbocharger is driven with a turbine driven by the engine s exhaust fuel. Compared with a mechanically driven supercharger, turbochargers are better, yet less sensitive. Twincharger pertains with an engine with both a supercharger along with a turbocharger.

Turbochargers are popular about truck, auto, train, aircraft, plus construction equipment machines. These are generally usually utilized with Otto cycle plus Diesel cycle internal combustion motors. They have additionally been found valuable inside automotive gas cells.

The turbocharger was invented inside the early 20th century by Alfred Bchi, a Swiss engineer as well as the head of diesel engine analysis at Gebruder Sulzer engine production organization inside Winterthur. Bchi particularly intended his device with be utilized about diesel motors. His patent of 1905 noted the efficiency improvements a turbocharger can bring with diesel machines that inside 1922 had initially been developed for employ inside road transportation.

At the time, metal plus bearing technologies wasn't sufficiently advanced with permit a useful turbocharger with be built. The initial useful turbodiesels were sea motors fitted with 2 German passenger liners - the Danzig as well as the Preussen inside 1923, every having 2 10-cylinder machines of 2,500 horsepower. By the late 1920s, many diesel engine builders were generating big turbodiesels for sea plus stationary employ, including Sulzer Bros., MAN, Daimler-Benz, plus Paxman.

Turbocharger technologies was improved greatly by developments throughout World War II plus next development of the fuel turbine. It was today potential with utilize small turbochargers about small, higher-speed motors. Diesel locomotives with turbodiesels started appearing inside the late 1940s plus 1950s.

In 1951 MAN presented a turbocharged variation of their MK26 truck, though it was not place into mass manufacturing. Series creation of turbocharged diesel pickups commenced inside 1954, whenever both MAN 750TL1 plus Volvo Titan Turbo were introduced with the markets. The building of the Interstate Highway System inside the USA from 1956 created long-distance road transportation of goods more appealing. To maintain with general traffic, more effective machines came inside improving need. Cummins, Detroit, plus CAT all had turbo-charging because a choice by the late-1960s. In Europe, legislation was introduced inside Germany mandating a minimal power-to-weight ratio for trucks; by the late 1960s, a 38-tonne comprise had with have at minimum 304 hp. Many producers met these requirement with large-displacement all-natural aspiration machines, several with all the way of large-displacement or turbo-charging, whilst Scania plus Volvo where amidst those which just offered turbocharged pickups which met the demands. Turbo-charging wasn't preferred initially because the motors were perceived with be less reliable, yet the way claimed a decisive victory by the mid-1970s because the 1973 oil crisis improved gas fees. The last marketplace to find the absolute penetration of turbo diesels was Japan, where legislation about particle emissions effectively mandated all-natural aspiration machines till efficient particle filters became accessible.

Experiments with small turbodiesels of the size right for a vehicle were carried out inside the 1960s. The Rover Company built experimental 2.5 liter 4-cylinder turbodiesels inside 1963, however didn't place the shape into creation. The initially turbodiesel creation automobile was the Mercedes-Benz 300SD, introduced inside May 1978. It utilized a Garrett AiResearch turbocharger, plus was yielded just for the United States. In Europe, the initial turbodiesel was the Peugeot 604 inside early 1979. Turbodiesel vehicles started with be commonly built plus available inside Europe throughout the late 1980s plus early 1990s, a trend which has continued with the modern. In France, due with a taxes structure that gave turbodiesels a comparative benefit, sales shot up earlier, achieving 33,000 passenger auto sales inside 1983.

On the other hand with turbochargers, superchargers are mechanically driven by the engine. Belts, stores, shafts, plus gears are prevalent techniques of powering a supercharger, placing a mechanical weight found on the engine. For instance, found on the single-stage single-speed supercharged Rolls-Royce Merlin engine, the supercharger utilizes regarding 150 horsepower. Yet the pros outweigh the costs; for the 150 hp with drive the supercharger the engine generates an more 400 horsepower, a web gain of 250 hp. This really is where the main downside of the supercharger becomes apparent; the engine should withstand the internet force output of the engine and the force with drive the supercharger.

Another downside of several superchargers is lower adiabatic efficiency than turbochargers. Adiabatic efficiency is a measure of the compressor s ability with compress air without adding extra heat to this air. Even beneath perfect conditions, the compression procedure usually results inside elevated output temperature; nevertheless, better compressors provide less extra heat. Roots superchargers impart more heat with the air than turbochargers. So, for a provided amount plus stress of air, the turbocharged air is cooler, plus because a outcome denser, containing more oxygen molecules, plus consequently more possible force than the supercharged air. In useful application the disparity amongst the 2 is dramatic, with turbochargers usually producing 15% with 30% more energy based entirely found on the variations inside adiabatic efficiency.

By comparison, a turbocharger refuses to spot a direct mechanical weight found on the engine, though turbochargers put exhaust back stress about motors, improving pumping losses. This really is better, considering whilst the improved back stress taxes the piston exhaust stroke, much of the power driving the turbine is offered by the still-expanding exhaust fuel which might otherwise be wasted because heat from the tailpipe. On the other hand to supercharging, the main downside of turbocharging is what exactly is called "lag" or "spool time". This really is the time amongst the need for an heighten inside force as well as the turbocharger providing improved intake stress, plus therefore improved force.

Throttle lag happens considering turbochargers depend found on the buildup of exhaust fuel stress with drive the turbine. In varying output systems including vehicle motors, exhaust fuel stress at idle, low engine speeds, or low throttle is normally insufficient with drive the turbine. Just whenever the engine reaches enough speed does the turbine section begin with spool up, or angle swiftly enough with provide intake stress above atmospheric stress.

A mixture of an exhaust-driven turbocharger plus an engine-driven supercharger may mitigate the weaknesses of both. This technique is known as twincharging.

In the case of Electro-Motive Diesel s two-stroke motors, the mechanically-assisted turbocharger is not especially a twincharger, because the engine utilizes the mechanical assistance with charge air just at lower engine speeds plus business. When above notch # 5, the engine utilizes true turbocharging. This differs from a turbocharger which utilizes the compressor section of the turbo-compressor just throughout beginning plus, because a two-stroke motors cannot naturally aspirate, plus, according with SAE definitions, a two-stroke engine with a mechanically-assisted compressor throughout idle plus low throttle is considered naturally aspirated.

Improvements inside force, gas economy, plus Noise, Vibration, plus Harshness inside both small- plus large-capacity turbodiesels over the last decade have spurred their popular adoption inside certain markets, notably inside Europe where they create up over 50% of modern vehicle registrations. Turbodiesels are considered more flexible for automotive uses than naturally aspirated diesels, that have sturdy low-speed torque outputs nevertheless shortage force at high speeds. Turbodiesels is tailored with have a more acceptable spread of both energy plus torque over their speed range or, when being built for commercial utilize, is tailored with better either torque or force at a provided speed depending found on the actual utilize. Naturally aspirated diesels, virtually without exception, have a lower force output than a petrol engine of the same capability while the same time requiring stronger internal components including the pistons plus crankshaft with withstand the better stresses of the diesel engine s running cycle. These factors provide naturally aspirated diesels a bad power-to-weight ratio. Turbocharger units weigh extremely small yet may provide immense energy, torque, plus efficiency improvements. Fitting a turbocharger could bring a diesel engine s power-to-weight ratio about the same level because an equal petrol device, generating turbodiesels desirable for automotive utilize, where producers aim for similar force outputs plus handling properties over their range, irrespective of the kind of force device selected.

A Mazda3 with a contemporary well-known rail 1.6 liter turbodiesel engine with varying geometry turbocharger, intercooler, 16 valves, double overhead camshafts plus piezo controlled 7-stage direct injection.

Turbochargers are inside several techniques more suited with procedure inside diesel motors. The small speed range which Diesel motors function inside mean which the turbocharger has with change speed less, reducing turbo lag plus improving efficiency. Diesel motors never need dump valves. Perhaps many greatly, the diesel engine is immune with detonation considering the gas is not injected till when of combustion. So, the compression ratio refuses to need to be reduced, or alternative anti-detonation measures taken, because will be needed for a turbocharged spark-ignition engine. The turbodiesel engine will equally assist with all the amount of torque it can provide out. Commonly employed inside pickups, it assists boost the towing ability of the truck, and also gas economy.

During the 1990s, turbodiesel machines were primarily employed inside the United States for light pickups. An illustration is the Ford Power Stroke engine series, installed about Ford F-Series Super Duty pickup pickups, the E-series vans as well as the Excursion sport utility cars. In 1989, Dodge began generating light duty pickups with 5.9 liter turbo-diesel engine.

As need for diesel motors inside standard sedan plus station wagon vehicles inside the United States has been much lower than inside saloon plus property vehicles inside Europe, the development of small automotive turbodiesels has been led by European producers inside latest years. Diesel gas inside the USA had a greatly high amount of sulphur than the gas selected inside Europe, that meant which diesel-engined vehicles from European machines had with either be fitted with specifically developed gas plus emissions control program for the North American marketplace, or couldn't be available because marketplace.

After ultra low sulphur diesel was introduced inside the United States inside October 2006, automakers started to provide turbodiesel models that may take benefit of it with minimize emissions. Manufacturers including Volkswagen, BMW, Audi, plus Mercedes-Benz have been releasing vehicles with 4 plus six-cylinder turbodiesels.

Availability of turbodiesel models improved inside the 2014 model year, because a limited more producers introduced passenger vehicles plus sport utility cars driven by turbodiesel motors. GM started marketing the 2014 Chevrolet Cruze Clean Turbo Diesel inside 2013. The Mazda6 fitted with all the SKYACTIV-D engine is obtainable in the late spring of 2014. The 2014 Jeep Grand Cherokee with all the 3.0L EcoDiesel V6 engine is accessible at the finish of 2013. Additionally, producers have began advertising vans plus light-duty pickups with turbodiesels again. The 2014 Ram 1500 is accessible with all the EcoDiesel engine inside March 2014. The 2015 Ford Transit van, with a 3.2L I-5 Power Stroke turbodiesel way, is obtainable in the summer of 2014. The next-generation Nissan Titan pickup truck, expected with be obtainable in 2014, can have a Cummins-sourced turbodiesel available

An Injection Pump is the device which pumps gas into the cylinders of the diesel engine. Traditionally, the injection pump is driven indirectly within the crankshaft by gears, stores or perhaps a toothed belt which moreover forces the camshaft. It rotates at half crankshaft speed inside a traditional four-stroke engine. Its timing is these which the gas is injected just rather somewhat before top dead centre of which cylinder s compression stroke. It is equally widespread for the pump belt about gasoline motors with be driven straight within the camshaft. In certain systems injection pressures is because significant because 210 MPa.

Earlier diesel pumps selected an in-line design with a series of cam-operated injection cylinders inside a line, very like a miniature inline engine. The pistons have a continual stroke amount, plus injection amount is controlled by rotating the cylinders against a cut-off port which aligns with a helical slot inside the cylinder. Whenever all cylinders are rotated at when, they simultaneously differ their injection amount with provide almost energy within the engine. Inline pumps nonetheless discover favour about big multi-cylinder motors like those about pickups, construction plant, static motors plus agricultural cars.

Distributor diesel injection pump

For employ about vehicles plus light pickups, the rotary pump or distributor pump was developed. It utilizes a single injection cylinder driven from an axial cam plate, that injects into the individual gas lines through a rotary distribution valve. Later incarnations including the Bosch VE pump fluctuate the injection timing with crank speed with let better force at excellent crank speeds, plus smoother, more affordable running at slower revs. Many VE variants have a pressure-based program which enables the injection amount with strengthen over general with let a turbocharger or supercharger prepared engine with develop more energy below boost conditions.

Inline diesel metering pump

All injection pumps include the governor with cut gas provide when the crank speed endangers the engine - the thick moving components of diesel machines never tolerate overspeeding perfectly, plus catastrophic damage may happen when they are over-revved. Poorly maintained plus used machines could consume their lubrication oil by used out crankcase ventilation systems plus run away , causing improving engine speed till the engine destroys itself. This really is considering many diesel motors just control their speed by gas provide control plus don t have a throttle valve with control air consumption.

Common rail direct gas injection is a contemporary variant of direct gas injection program for petrol plus diesel machines.

On diesel machines, it qualities a high-pressure gas rail feeding individual solenoid valves, because opposed with low-pressure gas pump feeding device injectors. Third-generation normal rail diesels today feature piezoelectric injectors for improved precision, with gas pressures as much as 3,000 bar.

Solenoid or piezoelectric valves create potential fine electronic control over the gas injection time plus amount, as well as the high stress which the normal rail technologies makes accessible delivers greater gas atomisation. To lower engine sound, the engine s electronic control device may inject a tiny amount of diesel before the principal injection event, therefore reducing its explosiveness plus vibration, and also optimising injection timing plus amount for variations inside gas standard, cold beginning and so forth. Some advanced usual rail gas systems work because various because five injections per stroke.

Common rail motors need the fairly brief with no heating-up time, depending about ambient temperature, plus provide lower engine sound plus emissions than elder systems.

Diesel machines have historically chosen numerous types of gas injection. Two prevalent kinds include the device injection program as well as the distributor/inline pump systems. While these elder systems offered exact gas amount plus injection timing control, they were limited by many factors:

They were cam driven, plus injection stress was proportional with engine speed. This usually meant which the greatest injection stress can just be attained at the greatest engine speed as well as the maximum achievable injection stress reduced because engine speed reduced. This relationship is true with all pumps, even those selected about popular rail systems. With device or distributor systems, the injection stress is linked with the instant stress of the single pumping event without accumulator, and therefore the relationship is much more prominent plus troublesome.

They were limited inside the amount plus timing of injection occasions which may be commanded throughout a single combustion event. While numerous injection occasions are potential with these elder systems, it's more difficult plus costly with achieve.

For the typical distributor/inline program, the begin of injection happened at a pre-determined stress plus ended at a pre-determined stress. This characteristic resulted from "dummy" injectors inside the cylinder head that opened plus shut at pressures determined by the spring preload used with the plunger inside the injector. When the stress inside the injector reached a pre-determined level, the plunger might lift plus injection might begin.

In popular rail systems, a high-pressure pump shops a reservoir of gas at excellent stress --- about plus above 2,000 bars. The expression "popular rail" pertains with the truth which the gas injectors are provided with a popular gas rail that is nothing over a stress accumulator where the gas is stored at excellent stress. This accumulator supplies numerous gas injectors with high-pressure gas. This simplifies the cause of the high-pressure pump because it just must keep the commanded stress at a target. The gas injectors are usually ECU-controlled. Whenever the gas injectors are electrically triggered, a hydraulic valve is mechanically or hydraulically opened plus gas is sprayed into the cylinders at the desired stress. Because the gas stress power is stored remotely as well as the injectors are electrically actuated, the injection stress at the begin plus end of injection is especially close to the stress inside the accumulator, therefore producing a square injection rate. If the accumulator, pump plus plumbing are sized correctly, the injection stress plus rate is the same for every of the several injection occasions.

The TDI engine utilizes direct injection, where a gas injector sprays atomised gas straight into the key combustion room of every cylinder, instead of the pre-combustion room common inside elder diesels that utilized indirect injection. The engine additionally utilizes forced induction through a turbocharger with strengthen the amount of air that is capable with enter the engine cylinders, plus many TDI machines furthermore feature an intercooler with lower the temperature of the charged , or compressed air within the turbo, therefore improving the amount of gas which is injected plus combusted. These, in combination, let for better engine efficiency, plus consequently better force outputs, when furthermore decreasing emissions plus providing more torque than the non-turbo plus non-direct injection petrol engined counterpart from VAG.

Similar technologies has been employed by additional automotive firms, yet "TDI" especially pertains with these Volkswagen Group machines. Naturally aspirated direct-injection diesel machines prepared by Volkswagen Group employ the Suction Diesel Injection label.

Because these machines are comparatively low displacement plus very compact they have a low surface location. The resulting reduced surface location of the direct injection diesel engine reduces heat losses, plus therefore increases engine efficiency, at the cost of somewhat improved combustion sound. A direct injection engine is furthermore simpler with commence whenever cold, due to better placing plus use of glowplugs.

Direct injection turbodiesel machines are frequent winners of numerous prizes inside the International Engine of the Year Awards. In 1999 inside certain, six from twelve categories were claimed by direct injection engines: 3 were Volkswagen, 2 were BMW, plus 1 Audi. Notably which year, the Volkswagen Group 1.2 TDI 3L beat the Toyota Prius with win "Best Fuel Economy" inside its class. The TDI engine has earned "Green Car of the Year award" inside the years 2009 plus 2010 whipping alternative numerous electrical vehicles.

Turbocharger lag is the time necessary with change force output inside reaction with a throttle change, observed because a hesitation or slowed throttle reaction whenever accelerating than a naturally aspirated engine. This really is due with the time required for the exhaust program plus turbocharger to create the necessary boost. Inertia, friction, plus compressor weight are the main contributors with turbocharger lag. Superchargers never suffer this condition, considering the turbine is eliminated due with the compressor being straight driven by the engine.

Turbocharger applications is classified into those which need changes inside output force plus those which never. While significant with differing levels, turbocharger lag is many challenging inside applications which need fast changes inside force output. Engine designs lessen lag inside a quantity of ways:

Lowering the rotational inertia of the turbocharger by utilizing lower radius components plus ceramic plus additional lighter materials

Changing the turbine s aspect ratio

Increasing upper-deck air stress plus improving wastegate response

Reducing bearing frictional losses, e.g., utilizing a foil bearing instead of a traditional oil bearing

With variable-nozzle or twin-scroll turbochargers

Decreasing the amount of the upper-deck piping

Utilizing several turbochargers sequentially or inside parallel

Utilizing an antilag system

Utilizing a turbocharger spool valve with heighten exhaust fuel flow speed with the turbine

You Might Also Like...

Software: ClickCartPro, Copyright 1999-2024 Kryptronic, Inc.

Exec Time: 0.136149 Seconds

Memory Usage: 2.658653 Megabytes

0 Items (Empty)

0 Items (Empty)

.png)