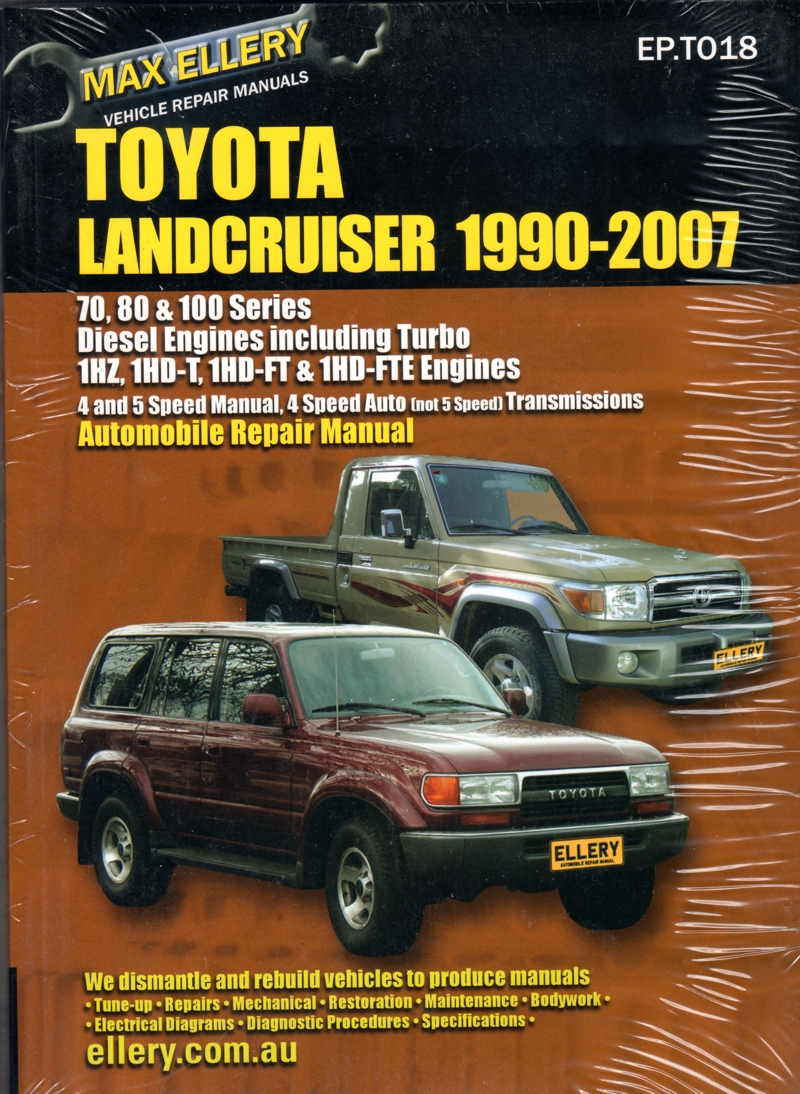

Toyota Landcruiser 1990 - 2007 Diesel 70 80 100 series Ellery Repair Manual - NEW

NEW 500 pagesToyota Landcruiser Diesel 1990-2007 70's, 80's & 100 Series Diesel including Turbo Other Toyota Car Repair Manuals click hereOther Toyota Landcruiser Repair Manuals click hereThis is an excellent manual with over 500 pages. It has step by step instructions covering all aspects of the vehicles. The manual Covers station wagons, utilities, troop carriers and tray models. The first chapter, "Engine tune-up and maintenance" guides you through the most basic maintenance and tune-up. It includes the specifications required, regardless of whether you are an owner wishing to change the oil, or a mechanic requiring specifications for tune-up and maintenance. Engine chapter - We have covered all 6 cylinder diesel engines, 1HZ, 1HD-T, 1HD-FT and 1HD-FTE that Toyota ran from 1990 to 2002. Turbocharged engines are included. This chapter is full of step by step instructions, plus plenty of photographs and line illustrations to give the reader explicit detail, suitable for everyone, regardless of whether you require minor engine work or a major rebuild. Transmission and Transfer chapters - 4 chapters (51 pages) cover all manual and automatic transmissions for these vehicles. Step by step instructions and photographs are included. Diesel fuel chapters cover both the conventional and ECD diesel injection systems for the above engines, including injectors, fuel pump and fuel tank. Brakes, Suspension, Steering, Rear Axle, etc all have independent chapters full of easy to follow photographs and instructions. Electrical Schematics and Fault codes approximately 130 pages are included. The Manual has an entire engine chapter which covers all 6 cylinder diesel engines: DOES NOT COVER 5 SPEED AUTOMATIC GEARBOX Diesel fuel chapters cover both the conventional and ECD Diesel Injection systems for the above engines, including injectors, fuel pump and fuel tank. Contents:

|

The Toyota Land Cruiser is a series of four-wheel drive vehicles produced by the Japanese car maker Toyota Motor Corporation. Development of the first generation Land Cruiser began in 1951 as Toyota's version of a Jeep-like vehicle and production started in 1954. The Land Cruiser has been produced in convertible, hardtop, station wagon, and utility truck versions, and it is currently Toyota's flagship 4WD vehicle. The Land Cruiser's reliability and longevity has led to huge popularity, especially in Australia where it is the best-selling full-size, body-on-frame, four-wheel drive vehicle.Toyota also extensively tests the Land Cruiser in the Australian outback—considered to be one of the toughest operating environments in terms of both temperature and terrain.

20 Series

20 Series Production 1955-1960

Assembly ARACO

Yoshiwara, Aichi, Japan

Body style(s) 2-door Softtop

2-door Hardtop

2-door pickup truck

4-door Station wagon

Layout FR layout

Engine(s) 3.9 L I6 F petrol

Wheelbase 2,710 mm (106.7 in)

* 1955 - The Second generation, 20 Series was introduced. It was designed to have more civilian appeal than the BJ for export reasons. It also had more stylish bodywork and a better ride thanks to longer four-plate leaf springs which had been adapted from the Toyota Light Truck. It had a more powerful 3.9-liter six-cylinder Type F gasoline engine. The interior of the vehicles were made more comfortable by moving the engine 120 mm (4.7 in) forward. The 20 Series still had no low range, but it had synchromesh on the third and fourth gears.

* 1958 - The first Station wagon Land Cruiser was introduced with an even longer 2,650 mm (104.3 in) wheelbase (the FJ35V; wagon and van). The FJ25 production started in Brazil being the first Toyota vehicle built outside Japan.

* 1957 - A 4-door Station Wagon was added as the FJ35V. Land Cruisers were first imported into Australia by B&D Motors as FJ25/28 cab chassis with Australian made bodies.They were the first Japanese cars to be regularly exported to the country and were initially used in the Snowy Mountains Hydroelectric Scheme.

40 Series

40 Series Toyota Land Cruiser (BJ40LV)

Also called Toyota Macho (Venezuela)

Production 1960-1984

Assembly ARACO

Yoshiwara,Aichi, Japan

Body style(s) 2-door Softtop

2-door Hardtop

2-door pickup truck

4-door Station wagon

Layout FR layout

Engine(s) 3.0 L I4 B diesel

3.9 L I6 F petrol

4.2 L I6 2F petrol

3.6 L I6 H diesel

Wheelbase 90 in (2286 mm)

Length 151.2 in (3840.5 mm)

Width 65.6 in (1666.2 mm)

Height Softtop 76.8 in (1950.7 mm)

Hardtop 78.8 in (2001.5 mm)

Curb weight Softtop 3,263 lb (1,480 kg)

Hardtop 3,427 lb (1,554 kg)

Fuel capacity 18.5 US gallons

Main article: Toyota FJ40

* 1960 - The 20 Series was upgraded to the now classic 40. Toyota made many production changes by buying new steel presses. Mechanically, the FJ40 was given a new 125 hp, 3.9 liter F engine and the Land Cruiser finally received low-range gearing. The Brazilian model was rebadged the Bandeirante and received a Mercedes-Benz built Diesel engine generating 78 hp.

* 1965 - Global production surpassed 50,000 vehicles.

The Land Cruiser was the best selling Toyota in the United States.

* 1968 - The 100,000th Land Cruiser was sold worldwide.

* 1972 - The 200,000th Land Cruiser was sold worldwide.

* 1973 - The 300,000th Land Cruiser was sold worldwide.

The first diesel Land Cruiser was introduced for export on long wheelbase models with a six-cylinder H engine.

* 1974 - A four-cylinder 3.0-liter B diesel was offered. The introduction of this engine boosted sales in Japan by putting the Land Cruiser in a lower tax compact Freight-car category than its 3.9-liter gasoline version. Note: the new B diesel engine was different from the B gasoline engine used in the original BJ.

* 1975 - The 3.9-liter gasoline engine was replaced by a larger, more powerful 4.2-liter 2F unit.

The FJ55 received front disc brakes.

* 1976 - United States-version FJ40 Land Cruisers received front disc brakes like the FJ55.

The Toyota Land Cruiser Association was founded in California.

* 1977 - The Irish Army took delivery of the first of 77 FJ45 Land Cruisers. Although fast, reliable and with good off-road performance the type tended to rust excessively in the wet Irish climate. A few which did not succumb to the effects of weather were repainted in gloss olive green and survive as ceremonial gun tractors at military funerals.

* 1978 - The first BJ / FJ40 and FJ55 models were officially sold in West Germany with both diesel (BJ40) and petrol engines (FJ40 /55).

* 1979 - United States-version FJ40s were updated this year with a new wider, square bezel surrounding the headlights.

Power steering and cooler were offered in FJ40s for the first time.

The diesel engine was improved, evolving into the 3.2-liter 2B only in Japan.

The 3.6-liter H diesel engine was optional in some markets.

* 1981 - the Diesel version received front disc brakes and the more powerful 3.4-liter 3B engine.

50 Series

50 Series Toyota Land Cruiser (FJ55LG)

Production 1967-1980

Assembly ARACO

Yoshiwara, Aichi, Japan

Body style(s) 4-door station wagon

Layout Front engine four-wheel drive

Engine(s) 3.9 L I6 F petrol

4.2 L I6 2F petrol

Transmission(s) 3 or 4-speed manual (J30, H41 or H42)

Wheelbase 2,710 mm (106.7 in)

Length 4,673 mm (184.0 in)

Width 1,710 mm (67.3 in)

Height 1,864 mm (73.4 in)

* 1967 - Production of the FJ55 began. The FJ55 was a 4-door station wagon version based on the FJ40's Drive-train, replacing the 4-Door FJ45V (I). It was colloquially known as the "Moose". It has also been referred to as a pig or an iron pig. The FJ55 had a longer wheelbase 2710 mm and was designed to be sold in North America and Australia.

* Jan 1975 saw the F engine replaced by the 2F engine. Unusually for Toyota, the model (e.g. FJ55) did not change.

* Model 56 is in Japan only, with 2F engine ( Jan. 1975 - Jul. 1980 ).

60 Series

60 Series

Toyota Land Cruiser (FJ62LG)

Also called Toyota Samurai (Venezuela)

Production 1980-1990

Assembly ARACO

Yoshiwara, Aichi, Japan

Body style(s) 4-door station wagon

Layout Front engine, four-wheel drive

Engine(s) 3.4 L I4 3B diesel

3.4 L I4 13B-T diesel turbo

4.2 L I6 2F petrol

4.0 L I6 3F petrol

4.0 L I6 2H diesel

4.0 L I6 12H-T diesel turbo

4.2 L I6 1HZ diesel

4.2 L I6 1HD-T diesel turbo

Transmission(s) 4-speed manual H41F or H42F

4-speed automatic A440F

5-speed manual H55F (non-US)

Wheelbase 2,730 mm (107.5 in)

Length 4,675 mm (184.1 in)

Width 1,800 mm (70.9 in)

Height 1,750 mm (68.9 in)

The original Toyota Land Cruiser FJ 60 was available for purchase from 1981 through 1987. It is a front engine four door wagon which has available seating of five to seven. It is well known in the off-roading community for its tremendous 4X4 capabilities, despite being somewhat limited by its poor departure angle. The FJ 60 was offered in the following solid exterior colors: Alpine White, Brown, Desert Beige, Freeborn Red, Royal Blue; and in the following metallic exterior colors: Charcoal Gray, Cognac, Gray-Blue, Rootbeer, Sky Blue, Stardust Silver. In contrast to the FJ 62, the FJ 60 exhibits the classic round Land Cruiser headlights which are replicated now on the retro-style FJ Cruiser.

* 1980 - The 60 series was introduced. While still retaining the rugged off-road characteristics of previous Land Cruisers, the 60 was designed to better compete in the emerging sport utility vehicle market. The 60 was given a variety of comforts like air conditioning, a rear heater and an upgraded interior. The FJ60's "2F" petrol engine was left unchanged from the "40" series while six-cylinder 4.0 litre 2H and four-cylinder 3.4 litre 3B diesel engines were added to the product line.

* 1981 - Land Cruiser sales surpassed 1 million and a high-roof version was introduced. The 60 was introduced to South Africa when a stock Land Cruiser competed in the Toyota 1000 km Desert Race in the punishing wilds of Botswana.

* 1984 - This was the final year for the 40. Specialist suppliers of aftermarket parts and restorers who return old FJ40s to better-than-new condition replace Toyota dealers as the main source of Land Cruiser expertise.

* 1984 - Alongside the 60, the Toyota Land Cruiser 70 Series were introduced.

* 1985 - The Direct-injection 12H-T and 13B-T turbodiesel engine were introduced.

* 1988 - The petrol engine was upgraded to a 4.0-litre 3F-E EFI engine. The FJ62G VX-Series was introduced allowing the Land Cruiser to be sold in Japan as a passenger vehicle.

* 1990 - The 80 series station wagon was introduced, replacing the 60. The 80 was initially offered with a choice of three engines; the 3F-E six-cylinder petrol engine, a six-cylinder the 1HZ diesel and 1HD-T direct injection turbodiesel.

* 1990 - All 80s sold in North America and Europe now have a full-time four-wheel drive system. In Japan, Africa and Australia, a part-time system was still available. 80s produced between 1990 and 1991 had an open centre differential which was lockable in 4HI and automatically locked in 4LO. From 1992 onward, vehicles with anti-lock brakes had a viscous coupling that sent a maximum of 30% torque to the non-slipping axle. The differential was lockable in 4HI and automatically locked in 4LO.

100 Series

In April 1998, the 100 series Land Cruiser was introduced to replace the 8-year-old 80 series.There are two distinct versions of the 100-series, the 100 and the 105. The two versions look very similar, but there are significant differences under the bodywork. Despite these differences and official model names, both the 100 and 105 are collectively known as the 100 series. The 105 carried over the majority of it’s chassis and powertrain from the 80-series with coil suspended solid axles front & rear, and straight-6 petrol and diesel engines. These models were only sold in African, Australian and South American markets. The 100 models were fitted with a slightly wider chassis, independent front suspension (IFS) and two new engines. The change to IFS was a first for a Land Cruiser, and was made (in combination with rack-and-pinion steering) to improve on-road handling. However it also limited the vehicle’s off-road capability and durability, hence the decision to offer the solid axle 105 models alongside the IFS 100 models in some markets. The table below identifies the range of 100 and 105 models and their worldwide availability.

Although the 100 and 105 bodies are identical, there are some exterior visual indications between the two. The most obvious is the front end of the vehicle often appearing lower than the rear on the 100 models, due to the IFS. The other indicator is the design of the wheels. The 100 models have almost flat wheel designs, while he 105 models have dished wheels. This difference allows the two versions to retain similar wheel tracks, even though the 100 has a significantly wider axle track to allow for the IFS system. The introduction of a V8 engine was also a first for a Land Cruiser, and was specifically intended to improve sales in the North-American market, where it was the only engine available. In Australia, the 100 V8 was initially only available in the range-topping GXV model, while entry and mid-range models were the 105 powered by the 1FZ-FE I6 petrol, or 1Hz diesel engines. The new 1HD-FTE turbo-diesel 100 was added to the Australian range in October 2000 after being available in Europe and the UK since launch in 1998. The 4WD media in Australia were critical of Toyota’s decision to offer the acclaimed 1HD-FTE engine only in combination with IFS. Australian 4WD Monthly magazine said "We will never forgive Toyota for going independent at the front with the mighty 4.2 turbo-diesel". The 100 series formed the basis for the Lexus LX470, which was also sold in Japan as the Toyota Cygnus. The 100 series was called the Toyota Land Cruiser Amazon in the UK and Ireland from 1998 to 2003. In 2000, Toyota celebrated the 50th anniversary of the Land Cruiser with commemorative models offered in several countries. Total global production to date was 3.72 million vehicles. The 100 series remained in production until late 2007, with several minor facelifts and specification changes introduced over the years.

Toyota Landcruiser 1990 - 2007 Diesel - Ellery Repair Manual NEW 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007

0 Items (Empty)

0 Items (Empty)

Landcruiser%20%2070%2080%20100%20series%20engine/3.%209781876720025__01189.1527817673.jpg width= height=/>Landcruiser%20%2070%2080%20100%20series%20engine/2.%209781876720025__01189.1527817673.jpg width= height=/>Landcruiser%20%2070%2080%20100%20series%20engine/1.%2051utvtvlptl._sx353_bo1%2C204%2C203%2C200_.jpg width=355 height=499/>Landcruiser%20%2070%2080%20100%20series%20engine/2.%20002-toyota-land-cruiser-79-series-pickup-engine-bay.jpg width=600 height=400/>Landcruiser%20%2070%2080%20100%20series%20engine/3.%20ellery-petrol-toyota-landcruiser-70-80-100-series-repair-manual.jpg width=400 height=430/>Landcruiser%20%2070%2080%20100%20series%20engine/4.%201004313492.jpg width=600 height=600/>

Landcruiser%20%2070%2080%20100%20series%20engine/3.%209781876720025__01189.1527817673.jpg width= height=/>Landcruiser%20%2070%2080%20100%20series%20engine/2.%209781876720025__01189.1527817673.jpg width= height=/>Landcruiser%20%2070%2080%20100%20series%20engine/1.%2051utvtvlptl._sx353_bo1%2C204%2C203%2C200_.jpg width=355 height=499/>Landcruiser%20%2070%2080%20100%20series%20engine/2.%20002-toyota-land-cruiser-79-series-pickup-engine-bay.jpg width=600 height=400/>Landcruiser%20%2070%2080%20100%20series%20engine/3.%20ellery-petrol-toyota-landcruiser-70-80-100-series-repair-manual.jpg width=400 height=430/>Landcruiser%20%2070%2080%20100%20series%20engine/4.%201004313492.jpg width=600 height=600/>