RAF Typhoon 1994 Onwards (All Marks) Haynes Owners Workshop Manuals

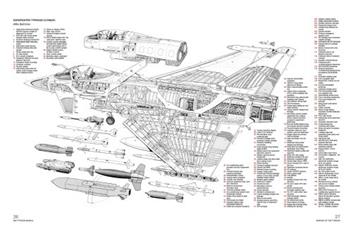

Hardcover - 160 pages - Highly capable and extremely agile, the RAF's Typhoon (Eurofighter) is a multi-role combat aircraft that is capable of being deployed across the full spectrum of air operations - from air policing, to peace support, through to high-intensity conflict. Contents: * The Typhoon Story * Anatomy of the Typhoon * The Typhoon's Beating Heart * Licensed to Kill * The Pilot's View * The Engineer's View * Typhoon in Service * QRA Typhoon Published with the full cooperation of the RAF, the Typhoon is given the Haynes Manual treatment and offers readers a unique insight into flying and maintaining the latest high-tech combat aircraft in the RAF's inventory.

| Stock Info: | Out of Print |

0 Items (Empty)

0 Items (Empty)